2021 New Product of the Year Award Winners

At The 2021 ASSEMBLY Show a total of 20 products were nominated across five categories. Check out the incredible 2021 New Product of the Year category winners below!

Assembly Machines & Systems

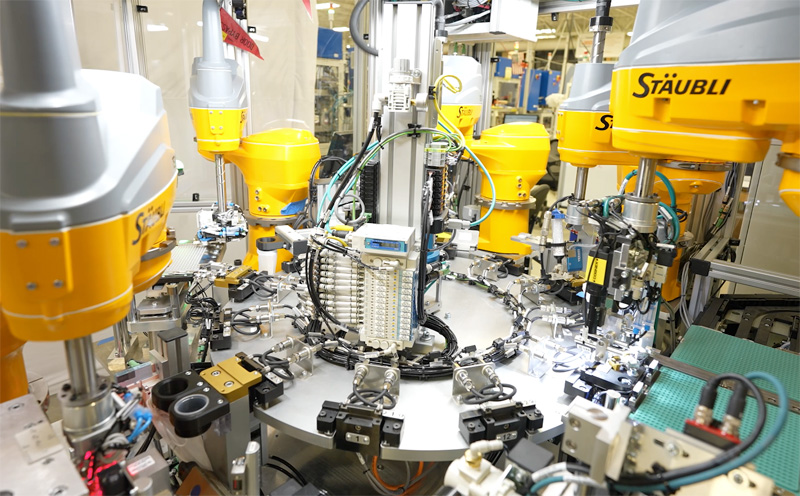

Automated Line Assembles Micron-Sized Parts

Automated Line Assembles Micron-Sized Parts

Lanco Integrated recently designed and built an automated assembly line to build three variants of a rice-sized subassembly for a microelectromechanical system used in consumer electronics and medical devices. Before this, the subassemblies were manually built. Engineers knew that working at the micron level meant that every part of the process would be subject to movement that could not be seen. They also wanted a space-efficient line, as well as one that requires minimal worker effort to change tooling. The line features a rotary dial, a pallet-transfer system, many compact workcells and 18 six-axis robots, which build subassemblies at a rate of 1,440 per hour with the help of machine vision. A comprehensive data collection system lets the customer monitor more than 500 different data points for each part as it moves through the assembly process.

Lanco Integrated

Booth 1205

207-773-2060

https://lancointegrated.com

Adhesives, Dispensing & Curing

Environmentally Friendly Pretreatment for Automotive Metals

Environmentally Friendly Pretreatment for Automotive Metals

Pallumina is a new, environmentally friendly pretreatment process for metal car and truck bodies prior to painting. The process improves paint adhesion to the vehicle body while preventing corrosion. The process is effective on all major metals, including 100 percent aluminum. Compared with conventional pretreatment processes, the new process cleans and prepares metal for painting in four steps rather than seven. The new process eliminates zinc, nickel and manganese phosphates and reduces sludge generation by up to 90 percent. In addition, it requires 40 percent less energy and 50 percent less water.

Henkel Corp.

Booth 605

800-562-8483

www.henkelna.com

Fastening Tools

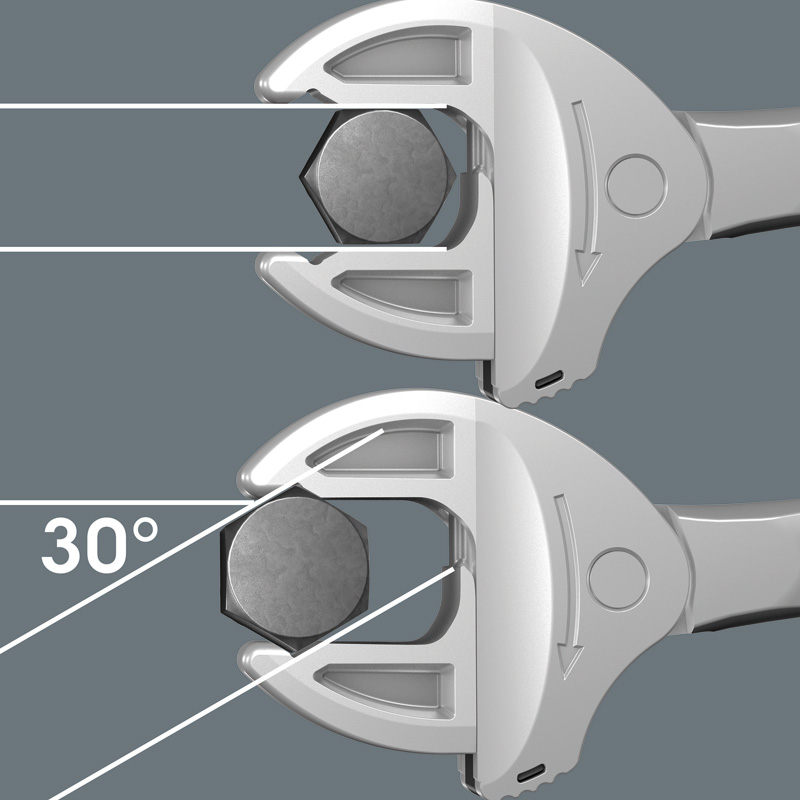

Self-Adjusting Ratcheting Wrenches

Self-Adjusting Ratcheting Wrenches

The 6004 Joker is a universal ratcheting wrench that automatically and continuously adjusts itself to tighten a range of fasteners in both metric and standard sizes. The hand tool is available in six sizes covering a total range of 7 to 32 millimeters or 1/4 to 15/16 inch. At its resting state, the mouth of the wrench is at its smallest size. Pressing the tool onto the fastener will cause it to automatically open and adjust precisely to the size of the fastener. No setting required by the user. The parallel smooth jaws allow surface pressure to be evenly distributed on the fastener, preventing fasteners from rounding out during power transmission. When pressure is taken off the tool, the jaws will relax enough to rotate the mouth around the fastener. It will readjust to grab either the point or flat of the fastener without ever having to remove the tool from the fastener, allowing the user to work quickly and use the wrench just like a ratchet. Due to the corner-width rectangular prism design in the mouth, a return angle of only 30 degrees can be achieved. This makes working in tight spaces easier.

Wera Tools

Booth 1500

800-267-5541

www.weratools.com

Robotics

Gripper Inspired by Geckos

Gripper Inspired by Geckos

Inspired by gecko feet, the ADHESO gripper consists of hundreds of fine polymer bristles that adhere to various materials without leaving a residue. It does not apply mechanical force to a part, but instead works on the principle of Van der Waals forces. To pick up a part, the gripper is gently pressed against it. The part is released by rotary, tilting or sliding movement, or with the help of an active wiper. Holes or other interruptions in the workpiece surface are no problem. The gripper does not require external power nor does it emit particles. It leaves no marks on the part when released. The gripper comes in four sizes. However, because it consists of bristles, it can be customized to the size and shape of the part. The size and types of filaments can also be optimized for holding force depending on the workpiece. It is ideal for gripping circuit boards, silicon wafers, or glass and plastic parts for medical devices.

SCHUNK

Booth 105

919-572-2705

www.schunk.com

Factory of the Future

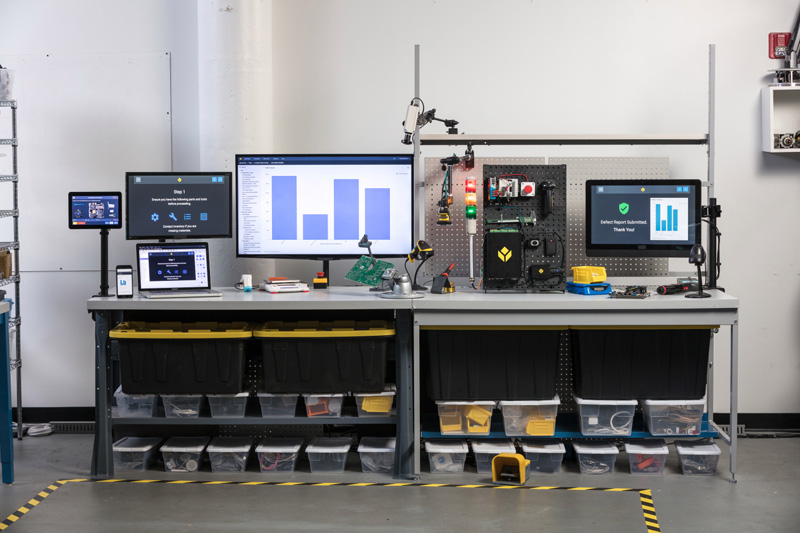

Library of Configurable Apps for Frontline Operations

Library of Configurable Apps for Frontline Operations

Tulip has published a newly upgraded version of its downloadable content library, which now features 60 configurable industrial apps, 12 app suites, 18 connectors and 100 device drivers to help manufacturers accelerate digital transformation. Tulip’s no-code frontline operations platform removes IT bottlenecks and enables citizen development of manufacturing software, allowing the teams closest to operations to own and update the systems that power their processes—while following company guidelines and fulfilling IT requirements. The apps enable assemblers to create and configure software that elevates their processes without locking them into vendor-specific data models and static applications that require heavy customization.

Tulip Interfaces

Booth 2012

833-468-8547

www.tulip.co