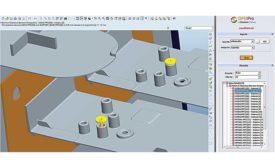

DFMA Assembly

Five Digital Transformation Failures and How to Avoid Them

Up to 70 percent of digital transformations fail: Don’t be one of them

May 15, 2020

Best Practices for Transitioning from Design to Assembly in Medical Device Manufacturing

Design Transfer Can Ensure a Smooth Product Development Process

January 7, 2020

Design for Additive Manufacturing

Several factors should be considered at the design stage to effectively produce parts using additive manufacturing methods.

March 1, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing