Automated Assembly Systems

There are many ways to boost productivity in pressing operations.

Read More

Options for Semiautomatic Dispensing

Handheld, powered dispensers provide the answer to many assemblers’ needs.

June 26, 2023

Best Practices for Semiautomatic Screwdriving

The cost of fasteners is often not as important as the cost of installing them.

June 25, 2023

Manual, Semiautomatic or Fully Automatic?

The degree of automation on an assembly line depends on such factors as production volume, variety, complexity and cost.

June 25, 2023

Robotics

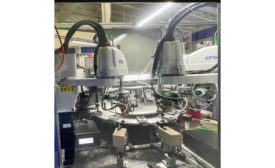

SCARA Robots Solder Circuit Assemblies

Electronics assembler’s DIY automation project saves money and increases efficiency.

May 8, 2023

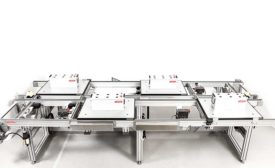

What’s New With Conveyors

Conveyors remain essential for getting parts to the right spot at the right time. Here’s a look at the state of the art.

May 5, 2023

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing