Home » Keywords: » plastic welding

Items Tagged with 'plastic welding'

ARTICLES

What’s New With Ultrasonic Welding

Advanced servo drives and immediate performance feedback are among the technologies that keep ultrasonic welding a go-to method for joining thermoplastic parts.

February 4, 2019

The ASSEMBLY Show Preview

Some 270 exhibitors will display the latest technologies at this year’s ASSEMBLY Show.

October 3, 2016

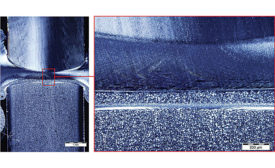

Welding Incompatible Thermoplastics

Incompatible thermoplastic polymers can be welded by using polymer blends that are compatible with both components.

September 8, 2016

The Benefits of Servo-Driven Ultrasonic Welding

Servo-driven ultrasonic welders can match welding speed to the melt flow rate of the plastic.

November 1, 2013

More Control for Ultrasonic Welding

The latest technology for ultrasonic plastic welding provides better process control and the tools to handle more part variations.

June 3, 2013

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing