Home » Keywords: » assembly conveyors

Items Tagged with 'assembly conveyors'

ARTICLES

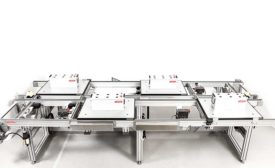

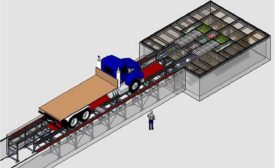

What’s New With Conveyors

Conveyors remain essential for getting parts to the right spot at the right time. Here’s a look at the state of the art.

May 5, 2023

Conveyor Case Studies

With the right conveyor, manufacturers can greatly improve their assembly, part feeding and packaging processes.

July 15, 2022

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing