Home » Keywords: » silicone adhesives

Items Tagged with 'silicone adhesives'

ARTICLES

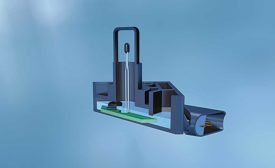

Silicone Adhesives for Medical Device Assembly

Consider these factors when choosing a silicone adhesive for medical device assembly.

January 10, 2023

Surface Preparation and Medical Silicone Adhesives

Cleaning and priming substrates prior to bonding can significantly improve adhesion

June 7, 2019

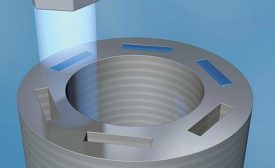

Alternative UV-Curing Adhesives

A new generation of UV-curing silicones and epoxies are increasingly being used in automotive and electronics applications.

March 6, 2018

Heat-Resistant Adhesives

Epoxies top the list of adhesive chemistries that can take the heat.

May 5, 2017

Conformal Coatings Protect Automotive Electronics

Conformal coatings protect and electrically insulate circuit board components from environmental stresses.

August 4, 2016

EVENTS

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing