Every assembly application involves multiple steps, but not every step presents the same level of difficulty. Before bonding parts, for example, an assembler will usually have little trouble preparing the dispensing system or fixturing parts. The bigger challenges involve selecting the right adhesive and making sure it is properly dispensed and cured.

Ammunition manufacturer Sellier and Bellot is familiar with these challenges, having faced them for many years while using a solvent-based sealant to seal the bullet and primer of various caliber ammunition (0.38, 0.40 S&W, 0.45, 0.357 and 0.308). Although dispensed automatically, the sealant required nearly a minute to cure and often caused the dispense valve to clog, resulting in low production rates.

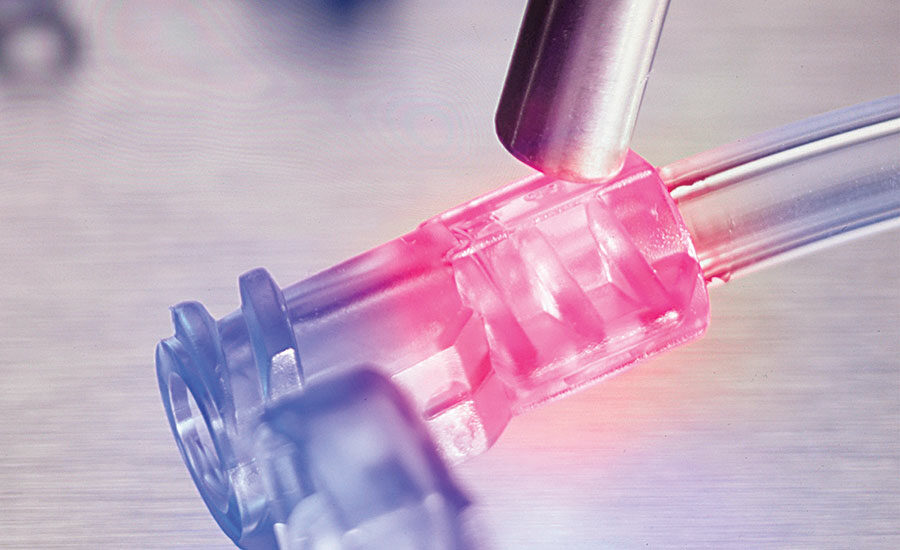

In the fall of 2013, Sellier and Bellot significantly increased productivity by switching to a custom system that dispenses and cures ultraviolet (UV)/anaerobic sealant. Made by Hernon Manufacturing Inc., the Autosealer 5500 system features a vibratory feeder bowl combined with robotic feeders, an HMI, conveyor belt, vision cameras, the SureShot 3500 dispenser and Ultracure 6 light (with mercury-arc bulb) for rapid curing.

Edgardo Rodriguez, director of sales and marketing at Hernon, says the system dispenses a micro-shot of sealant, cures it and then inspects and verifies its location on each bullet. At top speed, the system processes up to 300 bullets per minute. Its conveyor belt switches out in 15 minutes to accommodate different-caliber ammunition.

According to Rodriguez, the system also seals blank ammunition and is the first U.S.-made machine ever purchased by Sellier and Bellot in its 120-year history. A second system, featuring an LED light source for curing, will be installed later this year.

Manufacturers in many other industries, such as automotive, electronics and medical, face similar challenges when dispensing and curing UV adhesives. But, by following some simple best practices, assemblers can ensure a trouble-free bonding process.

A Bit About These Adhesives

In the late 1950s and early 1960s, chemists learned how to cross-link polymers using photoinitiators sensitive to UV light. When exposed to light of the correct wavelength and intensity, these photoinitiators decompose into free radicals that initiate the formation of monomer chains. After many propagation steps, the chains quickly polymerize and become fully cured.

By the 1970s, several UV-cure acrylics had been developed but were used primarily by dentists for fillings. In the 1980s, structural-strength and electronic-grade formulations were developed for industrial use. UV-cure silicones and epoxies appeared later that decade, followed by urethanes in the 1990s and cyanoacrylates several years ago. Some suppliers also offer custom hybrid formulations.

Initially, these adhesives were formulated to cure when exposed to bulbs (mercury arc, metal-halide, electrodeless, visible indium) that produce light in a fairly wide wavelength range (250 to 1,000 nanometers). At the start of this century, however, light-emitting diode (LED) suppliers began promising that this light source could cure UV adhesives more cost effectively.

Many manufacturers quickly replaced their bulbs with LEDs—only to realize that the LED’s narrow wavelength (365 to 405 nanometers) sometimes didn’t match the trigger of the adhesive’s photoinitiator. This mismatch prevented proper cure.

UV-adhesive suppliers responded by formulating adhesives specifically for use with LEDs. Besides eliminating the problem of wavelength mismatching, these adhesives help manufacturers obtain the benefits of LEDs along with those of UV cure.

LEDs last longer, generate less heat and can be used in more flexible configurations than bulbs.

UV adhesives are single-component materials that dispense easily, and allow precise part positioning for on-demand and quick curing. These capabilities make them well-suited for bonding, sealing, coating, gasketing, masking and potting applications.

For optimum part bonding, one substrate needs to be transparent so the UV light completely covers the joint interface. This design requirement is the reason UV-cure adhesives are used extensively with parts having clear plastic or glass features. Keep in mind, though, that certain clear plastics (like polycarbonate and polymethyl methacrylate) block UV light and require an adhesive that cures with visible light.

Some adhesives require only UV exposure to cure, while others feature a secondary mechanism to fully cure shadowed areas. An anaerobic mechanism, for example, cures these areas in the absence of oxygen. Air, heat (higher than 100 C) and ambient moisture (30 to 70 percent) are other common secondary mechanisms, which may require up to an hour for final cure.

Dymax Corp.’s line of Encompass UV-cure acrylic urethane adhesives incorporate the company’s Ultra-Red fluorescing and See-Cure color-change technologies. The adhesives are blue, but become colorless when cured and appear red under low-intensity black light. This allows inspectors to quickly and easily verify the adhesive is present and fully cured to the proper depth.

Loctite 4311 Flashcure, from Henkel Corp., is a UV-cure cyanoacrylate designed for various bonding applications. Bill Brown, manager of the automotive application engineering group at Henkel, says manufacturers in several industries use it for temporary part fixturing. Others use it to form a fillet joint (triangular-shaped adhesive bead) at one side of a substrate for extra strength. Other common uses include disposable medical devices and fiber-optic components.

The main drawbacks of UV-cure adhesives are they cost more than conventional adhesives, require special equipment for proper curing and offer a curing depth of only about 0.5 inch. Suppliers note, however, that formulations in the near future should be able to cure to a depth of about 1 inch.

“Each end-user must test to determine the minimum UV cure time required for each specific application,” explains Kevin Zoeller, engineering sales representative at Ellsworth Adhesives. “If it takes longer than 30 seconds to UV cure, the user is likely using the wrong UV lamp or the wrong UV adhesive for the application.”

Kept in the Dark

UV-cure adhesives do not require special dispensing systems. Standard time-pressure and positive-displacement systems can work just fine, so long as they meet two conditions. The first is that all wetted parts (plastic or metal) must be compatible with the adhesive. Incompatibility may cause material contamination or inadequate performance.

The other condition is all plastic components—feeder tube, syringe, dispense tip and fittings—need to be black, opaque or amber to block UV light. Suppliers make these parts by blending color resins into the liquid plastic prior to molding.

“When dispensing UV-cure materials with a pneumatic system, only use dry filtered air,” recommends Tom Muccino, business manager for adhesives packaging systems at Nordson EFD. “Air that has any moisture or even trace impurities, like oil, will cause fluid contamination. Or, if the adhesive is moisture-cure, it will harden in the syringe barrel.”

Muccino advises not to reuse disposable plastic components as an additional way to prevent material cross-contamination. He also advises using amber syringes that block UV light and use a barrel piston. Without a piston, air can enter the material. A piston also provides uniform emptying of the barrel and more-consistent deposits, without leaving residue on the syringe’s inner walls.

A couple years ago, an equipment manufacturer replaced its dispense valve with Nordson’s 752HF high-flow diaphragm valve to eliminate the creation of tiny air bubbles, which had formed due to outgassing from the UV adhesive. Muccino says the valve’s inert polymer diaphragm, which isolates the actuator from the valve, provides improved material flow.

The VD510-UV diaphragm valve from Fisnar Inc. offers precise flow control of low- to medium-viscosity (less than 35,000 cps) UV-cure materials. The valve is used frequently in automated dispensing applications and features wetted components made of ultra-high-molecular-weight polyethylene. Its minimum shot size is 0.001 cubic centimeter.

To avoid premature UV curing in the tip of the dispensing tool, system operators must always make sure that the UV light source is not located too close to the tip. It’s also important that they wear the proper safety clothing or use light-blocking curtains to protect themselves from UV exposure.

Dymax makes a wide range of UV-cure adhesives and coatings, including the SpeedMask line of temporary masking resins. Used in surface preparation and finishing operations, these resins come in several viscosities and are quickly applied by syringe or through dipping, spraying or screen printing. Resin 726-SC, for example, is LED-compatible and can be peeled or burned off after processing.

“End-users want complete volume control when dispensing,” claims Rodriguez. “Today that means being able to place adhesives with precision in microliter amounts.”

The Autobonder 2111 controller from Hernon ensures accurate, high-volume dispensing with the SureShot system. Weighing just 3 pounds, the controller can be operated automatically (after foot-pedal activation) or manually (using the foot pedal to stop and start dispensing). Material-flow-duration time is programmable from 0.01 to 99.99 seconds.

Find the Right Cure

Four types of UV curing systems are available, with part size and production volume determining which type is best for an application. Manual spot curing requires a worker to position a narrow light wand (5 to 12 millimeters wide) near a small part to initiate adhesive curing. For automated applications, extended-length wands are mounted just above the conveyor to ensure precise placement of the light on a treated area.

Flood curing is recommended for large parts or many parts simultaneously. Parts are placed below a light box, which is mounted on a stand, and the controller is turned on. Light projects downward, and within a few seconds, cures parts positioned in an area 4, 5 or 8 inches square.

A chamber curing system works similarly to a toaster oven. The worker places parts on a tray (6 to 18 inches square), slides it into the chamber and presses the start button, which automatically closes the light-box shutter and turns on the chamber light to initiate curing.

Conveyor curing systems are best suited for moderate to high-volume applications. The typical system consists of a conveyor mounted on a platform, and a curing section with light box centered over the conveyor.

Regardless of system type, the light intensity of a bulb or LED must be regularly monitored with a radiometer, says Mike Kay, director of product management at Excelitas Technologies. When the meter indicates the bulb or LED is below the required irradiance, adjust it immediately to maintain a repeatable curing process. Bulbs degrade faster over time, versus an LED. However, LEDs can be susceptible to rapid degradation if their system temperature exceeds specification.

“Depending on the application, bandpass filters may be necessary with a lamp to ensure proper cure and prevent part melting by limiting heat,” notes Kay. “Narrowband filters, for example, allow wavelengths of 320 to 390 nanometers to pass through, while 365-nanometer peak filters only allow a 365-nanometer wavelength.”

Earlier this year, Excelitas introduced the OmniCure AC9 series of high-output UV LED area curing systems. They produce high peak irradiance (14 watts per square centimeter) with custom optics to efficiently cure adhesives, coatings and inks. The six models are available with 395-nanometer wavelengths and feature an air-cooled curing area ranging from 50 to 300 millimeters in length. Kay says the systems are popular among printers, as well as electronics and automotive manufacturers.

Richard Levesque, systems integrator at Dymax, says manufacturers need to think of their dispensing and curing processes as one system—rather than two systems to be designed and maintained separately. He also says companies need to remember that today’s UV adhesives are more sensitive to light than ever and are formulated to cure quickly and completely at the lowest acceptable light intensity.

Last year, Dymax introduced the BlueWave LED flood system with three wavelengths (365, 385 and 405 nanometers). It features a 5-inch-square curing area and can be used as a stand-alone system or integrated into automated assembly lines. Cure times of 5 to 30 seconds are typical when using the company’s UV adhesives.