Construction equipment, farm tractors and other off-highway machines need more than just diesel engines, big tires and metal tracks to operate. They require hydraulic mechanisms to steer, raise booms, open buckets or tilt blades.

Most operators of backhoes, combines, concrete mixers and other machines never think about hydraulic motors and pumps. The devices are hidden out of sight. But, they play a vital role in performance, reliability and safety. They also help boost fuel efficiency and reduce emissions.

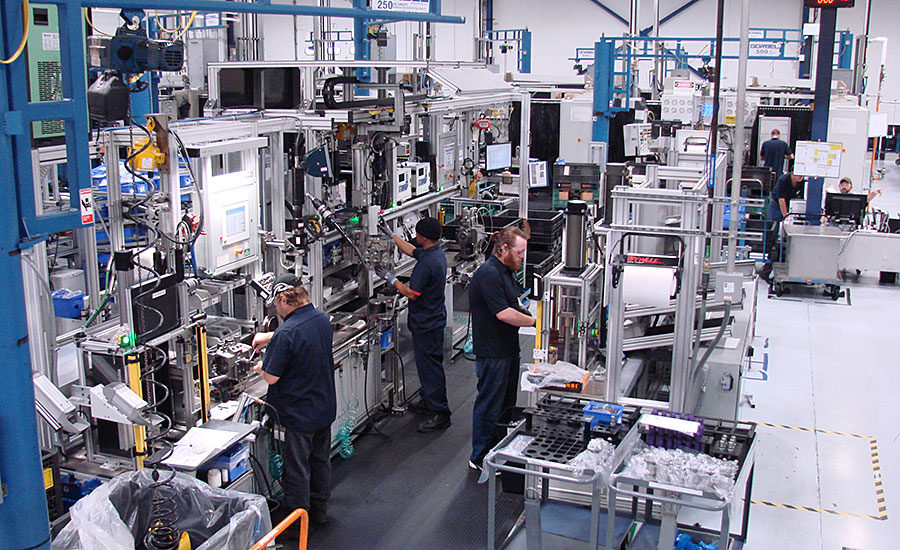

That’s why key players in the agricultural, construction, forestry, mining and material handling equipment industries rely on components made by Bosch Rexroth Corp. Many of those items are produced at the company’s state-of-the-art assembly plant in Fountain Inn, SC.

The high-mix, low-volume facility prides itself on timely delivery. In fact, the majority of the factory’s products are built to order.

Bosch Rexroth’s 100-acre manufacturing campus is vertically integrated and consists of three buildings. It includes two state-of-the-art machine shops, nine assembly lines, 21 test stands, two heat-treating facilities and a paint shop. The campus also houses engineering, product development, logistics and warehousing operations.

Bosch Rexroth is the global market leader for mobile hydraulics. It produces more than 5,000 different models and variations for both open- and closed-loop applications.

Fountain Inn is Bosch Rexroth’s largest manufacturing site in North America. It supports the company’s “local for local” strategy. Besides supplying key U.S. customers, the facility also exports to Brazil, Canada, China, India, Mexico and many European countries.

“Our main mission is to produce mobile hydraulics for the local market and to be No. 1 in driving America,” says Mike McCormick, vice president and plant manager. “This allows us to quickly respond to what our customers need to build their products.

“Bosch Rexroth has always emphasized quality, domestically manufactured products and customer satisfaction,” adds McCormick. “Our Fountain Inn plant has exemplified these priorities for the past 27 years.”

The facility originally consisted of a single 250,000 square-foot building when it opened in 1989. Today, the operation is more than twice that size.

“We believe in focusing on developing capabilities within our region that will help us serve our customers better—from engineering all the way through to the shipment of the final products,” says Paul Cooke, president and CEO of Bosch Rexroth Americas. “Fountain Inn is an excellent example, because we can not only deliver products faster, but we can also foster stronger relationships more directly with our customers earlier in the fulfillment cycle.

“Product performance can be reviewed and improved locally to exceed the expectations of our customers,” Cooke points out. “With this mentality embedded in our organizational DNA, we are confident that we can succeed in any challenge the customer places in front of our organization.”

Bosch Rexroth’s Fountain Inn facility is the recipient of the 2016 Assembly Plant of the Year award sponsored by ASSEMBLY magazine. The world-class plant was chosen for the 13th annual award because of the way that it ensures on-time delivery of high-quality products through the innovative use of automation, people, continuous improvement programs and flexible production processes.

“The team at Bosch Rexroth Fountain Inn has worked together over the past four years to double the size of our facility, while simultaneously driving significant improvements in our key performance metrics,” notes Cooke. “While we still have a long way to go to meet all of our ambitions, this team has shown what is possible by working together as a committed team to delight our customers.”

“This recognition is a milestone on our journey toward continuous excellence in serving our customers,” adds McCormick. “We know that our success is intimately linked to our ability to provide our customers with the best products and services.

“This, in turn, requires intense focus on execution and performance,” explains McCormick. “This drives innovation, especially in the assembly of our products.

“Our key investments over the past four years have improved our assembly technology and the related lean logistics to support it,” says McCormick. “Our assembly lines have been radically reformed in a relatively short time.

“In 2008, we used simple benchtop assembly methods with only basic hand tools,” McCormick points out. “Today, our assembly lines use numerous advanced technologies to simultaneously reduce cost and improve quality.”

Proud Heritage

Bosch Rexroth supplies more than 500,000 customers around the world with a wide variety of products for driving, controlling and moving machinery used in industrial and mobile applications. The popular brand traces its roots to a couple of German entrepreneurs: Robert Bosch and Georg Ludwig Rexroth.

In 1795, Georg Ludwig Rexroth acquired a water-powered hammer mill in Elsavatal, Germany. By 1830, the operation consisted of 100 people operating seven forges powered by four water wheels.

Rexroth acquired an iron foundry in Lohr, Germany, in the mid-19th century and gained a reputation for producing high-quality products.

In 1952, the company began making hydraulic components. The following year, Rexroth unveiled its first gear pump for mobile machines.

By the early 1970s, the company was a leader in developing new technology. Its hydraulic servo valves and proportional valve electronics revolutionized the construction equipment industry.

In 1975, Rexroth became a wholly owned subsidiary of Mannesmann AG. A merger in 2001 between Mannesmann Rexroth AG and Bosch Automation Technology created Bosch Rexroth AG.

In addition to being a leading manufacturer of hydraulic systems, the $6 billion company, which operates as a subsidiary of the Bosch Group, focuses on electric drives and controls, linear motion systems and assembly technology.

The Fountain Inn campus is one of four Bosch Rexroth manufacturing facilities in the United States. Additional plants are located in Bethlehem, PA; Charlotte, NC; and Hoffman Estates, IL.

Bosch traces its roots to 1886. That’s when Robert Bosch opened a small workshop in Stuttgart, Germany, for “precision mechanics and electrical engineering.”

Early products included telephones and electrical water-level indicators. However, within a decade, magneto ignition systems accounted for more than 50 percent of Bosch’s business, spurred by the fledgling auto industry.

Bosch eventually expanded into headlamps, horns, spark plugs, starters, windshield wipers and other types of automotive parts. Over the decades, the company diversified into consumer products by acquiring companies that made products such as dishwashers, film projectors, radios, refrigerators and water heaters.

Today, the Bosch Group is a diversified manufacturer based in Stuttgart. A majority of the company is owned by the Robert Bosch Foundation, a nonprofit charitable trust that supports diverse causes ranging from cancer research to improving the quality of schools.

The $78 billion company is a leading manufacturer of household appliances, packaging equipment, power tools, security systems and other products. Bosch also is the world’s No. 1 auto parts supplier. It is active in a wide variety of mobility technologies, such as brakes, direct injection, driver assistance, emissions control, powertrain, steering and thermal management systems.

Multiple Variables

The 2016 Assembly Plant of the Year specializes in fixed and variable hydraulic motors and pumps.

Fixed and variable products look similar, but typically a pump weighs twice as much as a motor. Each product contains different types of components on the inside for their functional purposes. In particular, the control mechanism adds significant weight.

“Pumps are typically more complex than motors,” says Joerg Schaeuble, director of operations. “One reason is that a pump can be the driving element of the power train and, therefore, typically controls itself and the downstream motor.

“This includes electro-proportional control valves and other electronics that control the machine,” adds Schaeuble. “So, it is easier to integrate a customer’s machine performance attributes into a pump, which itself is located close to the primary mover of the equipment (a diesel engine).

“Additionally, in a closed-loop system, the swashplate pump is the only component that can switch pressure ports easily with full variability under full pressure,” Schaeuble points out. “Motors (typically a bent-axis unit) have a minimum and a maximum position for performance, but they cannot swivel through the zero or neutral point.

“This is why the high-pressure port on a pump can be the A or the B port: both have the same performance characteristics,” explains Schaeuble. “Many safety features, such as high-pressure relief and pressure override, are also located in the pump.”

Hydraulic motors and pumps are used in all sizes, shapes and types of mobile equipment. Everything from cranes, dozers and excavators to backhoes, skid loaders and sprayers demands fluid power.

The typical piece of construction equipment requires several hydraulic motors and pumps to operate. However, the number of components depends on the application. For instance, mini excavators can run all functions with just one pump, while a traditional full-size excavator requires several pumps.

Bosch Rexroth’s customers include companies such as AGCO, Bobcat, Caterpillar, CNH, Deere, Doosan, Fendt, Gehl, Gradall, JCB, Liebherr and Sany.

“Our largest customers have their R&D headquarters in North America,” says McCormick. “That enables us to work closely with them and build products that help them meet tough emission regulations, while increasing productivity and reliability at the same time.”

Market Challenges

Bosch Rexroth Fountain Inn prides itself on customization. Its customers can select from various types of controls, electrical connectors, calibration settings, displacements, port configurations, mounting flanges and driveshafts.

Other options include filters, seals and valves. And, single pumps can be assembled together into tandems or triples.

“Theoretically, we can offer our customers an unlimited number of variations, depending on their specific application,” says Schaeuble. “The typical variation ranges between 5,000 and 10,000 different configurations in annual volumes ranging from one piece to thousands of pieces.”

Bosch Rexroth Fountain Inn assembles four main product families: A22VG and A24VG axial-piston, variable-displacement double pumps; A10VO/31 and A10VO/52 variable-displacement pumps; A4VG/32 and A10VG variable pumps; and Rineer high-torque vane motors.

A22VG and A24VG pumps feature two axial piston rotary groups and are engineered for hydrostatic drives in closed-loop circuits. They feature a high power rating in a compact design for medium- and heavy-duty applications.

A10VO/31 and A10VO/52 pumps feature a compact design. They feature low noise, a favorable power-to-weight ratio and excellent electrohydraulic pressure control. The cost-effective alternative to constant pumps is used on smaller power classes of mobile machinery.

A4VG/32 and A10VG pumps are used in hydrostatic drive configurations for heavy- and medium-duty applications. They cover a wide range of nominal sizes, providing mobile and industrial customers energy efficiency and a range of power-optimized configurations to choose from.

Rineer motors use a patented “vane crossing vane” design. The powerful units provide high torque from start and stall, with virtually flat torque curves. They are designed for tough jobs, such as powering top drives, power swivels and power tongs used on oil and gas drilling rigs.

Bosch Rexroth Fountain Inn has seen the market for its products grow increasingly volatile in recent years.

“Large fluctuations are much more common now,” says Schaeuble. “Simultaneously, our customers are asking for on-time delivery improvements, as well as technical features that customize the product even more to their needs. With a global supply chain supporting our value streams, this brought increased challenges upon our delivery capability.”

The A22 product line sells 95 percent of its output to large American off-highway construction equipment manufacturers. This segment was hit hard during the 2008-2009 economic downturn. It recovered quickly in 2010, but it currently operates below prerecession levels.

“The challenge was to adjust the assembly line to new applications and customers in new machines, which resulted in innovative variations in the assembly process,” notes Schaeuble. “Delivery performance, as a central indicator for customer satisfaction, dropped in 2014 to unacceptable levels because of the market volatility and the technical challenges that customers presented to us.

“In 2015, through a dedicated collaboration with our customers, including our customer-care teams and an interdepartmental approach concerning quality, we reached a delivery performance of more than 95 percent in the last quarter,” adds Schaeuble. “In 2016, we have not fallen below that mark and continue to enjoy the fruits of the systems and the collaboration we developed last year.”

Another challenge facing Bosch Rexroth Fountain Inn is a strict new emission regulation that’s forcing off-highway equipment users to invest in next-generation products equipped with electronic control modules and after-treatment components, such as diesel particulate filters. The Tier 4 mandate, which calls for a drastic reduction in diesel emissions, has created one of the biggest engineering challenges to ever confront the off-highway industry.

Construction, mining and agriculture engines are constantly changing speed. An engine’s duty cycle varies dramatically by the kind of job it’s employed at, as well as other things that affect engine performance, such as intake and exhaust temperatures, and the amount of dust in the air.

A wheel loader, for example, typically drives into a pile of dirt, rock or other material, lifts, backs, turns and travels to a dump site, then deposits its load. The whole duty cycle repeats every 40 seconds or so.

Reducing emissions under fluctuating load and throttle positions is no easy task. Other factors include hotter working conditions and small engine envelopes that limit the size of components.

To achieve those goals, manufacturers of bulldozers, excavators, harvesters and other mobile machinery are building products with smaller motors and reduced motor speeds. Bosch Rexroth engineers developed innovative solutions to address those needs, such as linking diesel motors with hydraulic controls to reduce fuel consumption by up to 20 percent without affecting performance.

Today, engines equipped with exhaust gas after-treatment systems have become standard in off-highway equipment. As a consequence, under-the-hood packaging is extremely tight. There is less space available for the installation of hydraulic motors and pumps in mobile machines than in earlier vehicle generations.

“The displacements of our pumps need to match diesel engines performance-wise,” says McCormick. “As a result, we had to change most of our products to accommodate the new Tier 4 rules.

“We calibrate each pump we produce to our customers’ unique specifications,” adds McCormick. “Although two pumps may operate the same mechanically, they could perform differently on a machine due to pressure flow variables dictated by things such as engine horsepower or torque.”

Plant Expansion

In 2013, Bosch Rexroth embarked on an $80 million, five-year journey to expand production on the Fountain Inn campus. The first step was to acquire a nearby 260,000-square-foot building that previously served as a warehouse for a pharmaceutical company.

The legacy building is now devoted to the machining and assembly of hydrostatic VG products. It includes four assembly lines, in addition to a heat treating facility and a paint shop.

Sandwiched between the old and new production buildings is a facility that houses logistics and shipping operations. A large area is also devoted to remanufacturing, spare parts and repairs, which is an important piece of Bosch Rexroth’s business strategy.

Bosch Rexroth engineers retrofitted the third building to produce open-loop products, such as its popular VO-series of variable displacement pumps.

The newest facility features five assembly lines, including an automated line equipped with a palletized conveyor that replaced three former lines. The vertically integrated facility includes a state-of-the-art machining operation that produces a wide variety of metal parts in-house, such as cylinders, driveshafts, housings and port blocks.

“We have mastered a lot of complex processes,” says McCormick. “The challenge is to do this with small lot sizes and high part tolerances.

“The degree of vertical integration varies depending on the product type and volumes,” adds McCormick. “To meet market-driven lead times, we retain the capability to manufacture many of our components in-house, while in parallel developing partners that can supply higher volumes, as needed, to meet overall market demand.”

The recent campus expansion project also includes additional product engineering and R&D resources. Its newest feature is an outdoor off-highway equipment proving ground that allows engineers to test hydraulic motors and pumps on their customers’ equipment.

“This will allow for quicker innovation, rapid prototyping and ensure faster customer response,” explains McCormick. “Continuous improvement of our value streams is now a fully internalized approach, allowing us to work together to drive our customers’ success.

“A significant increase in local engineering capabilities, such as the proving ground, will enable us to quickly and swiftly react to the marketplace,” adds McCormick. “Product performance can be reviewed and improved locally to exceed the expectations of our customers.”

The recent expansion almost doubled the number of Fountain Inn employees from 400 to 700. To help ensure a future workforce, the campus features an apprentice shop where young trainees can acquire the hands-on skills needed to operate the company’s production systems.

Apprentices work at Bosch Rexroth and attend classes at Greenville Technical College to gain advanced manufacturing skills. Since it started in 2008, 40 students have successfully completed the program.

Apprentices get experience in a fabrication shop, machine shop, sign shop and engineering co-op programs. Bosch Rexroth also offers apprentice programs for mechatronics and hydraulics manufacturing, as well as a youth apprenticeship for high school students that includes participation in the FIRST Robotics competition.

During their two-year tenure, students are on a six-month rotation. During this time, they are exposed to nonmachining related topics, such as assembly, test, quality inspection, tool management and tool setting, as well as some logistical functions.

The expansion also allowed Bosch Rexroth engineers to optimize value streams and rethink material handling systems at the Fountain Inn plant.

“It gave us a white canvas to create the best material flow and best layout using lessons learned in our legacy building,” says McCormick. “Our logistics organization now allows us to be extremely flexible.

“In our high-mix, low-volume environment, we’re able to easily accommodate orders that can be as low as one to five pieces,” claims McCormick. “Kitting is the key to doing that efficiently.”

“Our next-generation system integrates material handling and logistics into the assembly process,” notes McCormick. “We’re also building in flexibility and intelligence at individual workstations.”

The Fountain Inn plant is currently in the process of transitioning to a 100 percent kitting process. The lean material handling initiative aims to improve the quality and cleanliness of parts presentation to the line, in addition to streamlined material flow and overall efficiency. Small parts are presented with recyclable packaging in a way that prevents contamination from debris and airborne contaminants.

The new system relies on totes and tuggers to deliver parts to the assembly line instead of bulk containers delivered by forklifts. This will result in better use of floor space, creating a 60 percent smaller footprint. Additional benefits include increased throughput and improved delivery.

Bosch Rexroth Fountain Inn has experienced an extremely dynamic market for its products in recent years. Volumes across the thousands of variants can fluctuate up to 100 percent from one year to the next. Volumes can also fluctuate dramatically within a few months.

“This has driven us to rethink our value stream design, especially with respect to information flow,” says Schaeuble. “In our complex environment, information is the most important data to drive performance, including throughput.

“Products that were once ordered with a lead time of three to four months are now able to be ordered via mobile phone apps with delivery within 10 days for selected part numbers,” Schaeuble points out. “This is known as the Go-To Focused Delivery Program.”

The additional resources at Fountain Inn have expanded Bosch Rexroth’s shipping capabilities in North America. It now has the capacity to quickly deliver high-demand products, such as the A10VO pump, to customers in the region.

“The assembly throughput improvement was not driven by sales, but by cost reduction,” explains Schaeuble. “It was mainly the reduction of castings available for machining (changed to a supplier kanban system), as well as the stock of other finished components. The main reduction took place in the reduction of units between assembly and test.

“Where we usually kept about 12 hours of work, we currently operate with eight hours or less to make sure the product moves quickly through the assembly and test process,” adds Schaeuble. “Our ultimate goal is to have the product ready to go to the customer 24 hours after the first component has been assembled. But, there is far more development of the value stream necessary to achieve this goal.”

Lean Production Tools

The Bosch Production System (BPS) forms the heart and soul of all daily activities within the Fountain Inn plant. The 14-year-old initiative aims to increase customer satisfaction and value contribution by continually improving quality, cost and delivery.

“BPS focuses on waste reduction,” says McCormick. “Any kind of waste elimination, such as wasted motion or inventory, is an opportunity for us to improve our cost and competitiveness.”

To address those issues, the Fountain Inn plant is equipped with numerous visual management systems. White boards and value stream scoreboards display key performance indicators such as quality, safety and delivery performance.

“We see continuous improvement as a basic leadership principle and not as a special program layered over the existing leadership tasks,” says Jim Kressler, director of manufacturing. “A continuous improvement program (CIP) is used to manage all aspects of our business, from CNC machining to creation of purchase orders.

“We cannot imagine another way to run a production plant today,” notes Kressler. “The key drivers of any CIP activity are always data and empowerment: data to show the opportunities and empowerment to bring all associates into the improvement process.”

On the main assembly lines, this means daily monitoring of performance, as well as reviewing the challenges that occurred the day before. A CIP board accessible to all employees tracks customer data and internal data. Defined team members, including management, meet on a daily basis to discuss results and define actions as necessary.

“Special projects, such as the introduction of a fixed build schedule, tie back to the overall value stream system CIP and therefore get their own tracking boards, but they are still accessible to all employees,” adds Schaeuble. “On a weekly basis, the whole team comes together, and the shop floor team leader updates the team about the progress. This system is used in assembly, as well as in machining, and has helped us tremendously to improve the performance of the main value streams.

“We use BPS to drive continuous improvement,” explains Schaeuble. “Value stream mapping (VSM) is a key tool to translate our processes into a visual format that shows us our next improvement needs.

“We use the VSM results to prioritize projects and align resources,” says Schaeuble. “This becomes our System CIP roadmap. Our goal is to drive System CIP directly from these top priorities, followed by Point CIP, to ensure sustained results in the value streams.

“In a recent CIP project, we reduced changeover losses by 30 percent without increasing lot sizes,” notes Schaeuble. “VSM also helped us streamline the kitting process, as well as the material flow of the components into the assembly line. That is, we use this tool for both direct and indirect processes.

“It all starts with our PAR (positive associate relations) strategy,” explains Schaeuble. “Each employee is not seen as a production factor, but as a valuable resource that enables the organization to grow and be more competitive.

“Regular, open and honest communication with employees about the status of the business is the key to this effort,” claims Schaeuble. “We provide weekly updates to individual groups and have quarterly meetings where the business, internal and external challenges are discussed across shifts and across the different functions.”

Another key initiative is the Bright Ideas Program, which the Fountain Inn plant implemented in January 2015. All employees are encouraged to fill out 4.25-by 8.5-inch continuous improvement idea cards. The cards are color-coded green for work area and standards; pink for quality; and orange for safety ideas.

Last year, the program generated more than 1,200 ideas. The implementation of the ideas formulated on 30 cards alone resulted in $400,000 in savings.

There were ideas for safety improvements, process improvements, workplace organization improvements and quality improvements. Cards and results are visible to employees through Bright Ideas Boards, which are located in all departments in the plant.

An award system called Way to Go is a quick way for a manager to reward employees for going above and beyond the call of duty with a $25 gift card.

Flexible Factory

Quick changeover plays a key role in the success of the 2016 Assembly Plant of the Year.

“Our assembly lines can be changed over within one product cycle,” says Schaeuble. “This was a key design requirement when the lines were built. The equipment is programmed in a fashion that allows changeover station by station.

“In addition to the technical aspects of changeover, we also benefit from engagement of our associates in continuous improvement of changeovers,” adds Schaeuble. “For example, changeover sequence is optimized by the complete value stream team to ensure the most efficient use of our capacity.

“The tools we use to change over were simplified with input from employees,” Schaeuble points out. “This led to innovative adaptor designs that are faster and easier to handle rather than complete tool exchanges. Overall, we have seen a 40 percent reduction in changeover losses in that bottleneck station.”

Capacity issues can be addressed through overtime and weekend shifts as necessary. The specific assembly process is optimized for each value stream based on the design of the product.

At Bosch Rexroth Fountain Inn, the assembly process starts with the kitting of each customer order with all required components. After this, a serial number plate is affixed to the product and serves as the process control element throughout assembly.

“The subsequent process sequence for each value stream is somewhat different, but normally consists of bearing package assembly, rotating group assembly, final assembly and leak testing,” explains Schaeuble. “Each value stream has a maximum lot size regardless of the customer order size. This allows us to optimize all other support processes and planning to fit with the lot size.”

All controlled documents, including work instructions, are stored on a computer network that is accessible on each individual line. Assemblers can view the latest version of drawings, instructions and other information at any time.

To assemble a hydraulic motor or pump, operators start with a cast-iron housing that typically weighs about 45 pounds. “More than 20 different housings are used on the A22VG line alone,” says Bruce Woodward, assembly and test engineer. “By the time a pump is fully assembled, it weighs more than 100 pounds.”

Because of those heavy loads, all of the assembly lines are equipped with jib cranes and ergonomic lift-assist devices.

Assemblers manually install bearings, cylinders, driveshafts, filters, gaskets, O-rings, pistons, plugs, seals, valves and other components. Units are attached with a variety of fasteners. For instance, pumps typically require four rivets, a minimum of eight bolts, and anywhere from three to eight threaded steel or plastic plugs.

Bosch Rexroth Fountain Inn uses many types of fastening tools on its assembly lines, including air, DC-electric and battery-powered devices.

“Air tools are typically used for assembly processes that do not require a precise control of torque and angle, such as the installation of break-off plugs,” says Woodward. “These tools are also used to prepare our products for function testing, such as connectors on the test stand and removable covers.”

DC-electric fastening tools are used for all connections that are critical for the function of the pump, including valves, controls and plugs. Both torque and angle are monitored.

Battery-powered screwdrivers are typically used in low-torque applications, such as installing fittings for in-line leak testing.

Because Bosch Rexroth happens to be a leading supplier of production tools, the Fountain Inn assembly lines use the company’s state-of-the art screwdrivers.

“We extensively use ErgoSpin handheld nutrunners, combined with an HMI developed by Bosch Rexroth,” says Schaeuble. “These tools streamline the processes used in assembly and enforce a uniform application of the assembly standards for all products made in Fountain Inn. As a result, the assembly process has become much more predictable and reliable.

“ErgoSpin tools are mainly used to verify critical connections for our customers,” Schaeuble points out. “Part of our zero-defect strategy is to use and monitor the data coming out of these systems for the benefit of our customers, as well as internal operations. The implementation of these systems has resulted in improvements to our assembly process stability.”

Bosch Rexroth structural framing systems are also widely used throughout the Fountain Inn plant. The modular aluminum pieces, which can be easily connected together, are used for base structures, flow racks, workstations and white boards.

Servo presses are used on the assembly lines to attach driveshafts, flanges and other components. “Equipped with force and distance measurement, these machines enable us to detect any minor variations in our product and alert us to trends in component geometry,” says Schaeuble.

“We use in-line leak testing after assembly to ensure an absolute leak-free product is delivered to our customers,” adds Schaeuble. “Depending on the value stream and product, we select the most sensitive leak-test process, primarily pressure decay and mass flow. As with other key quality attributes, the leak test results are archived by serial number for the expected life of our product in the field.”

Last year, Bosch Rexroth engineers developed an assembly sequencing program to improve quality at the Fountain Inn plant. The program guides operators through the assembly process. It prevents an operator from starting a new operation at the beginning of the line until a certain operation at the end of the line is complete. This dropped detected assembly errors from about 15,000 parts per million per day to 0.

The leak testing operation was also improved to address a common customer complaint. “Failures were analyzed and actions were taken, and we were able to increase the sensitivity for the equipment to find even miniscule deficiencies,” says Schaeuble. “This led to an 85 percent reduction in leak-related customer complaints.

“From an overall facility standpoint, that project resulted in a drop of customer complaints by more than 40 percent from to 2013 to 2014, and another 20 percent from 2014 to 2015,” claims Schaeuble. “Based on current data, we expect to see a further reduction this year.”

Bosch Rexroth engineers have also implemented machine vision systems to improve quality yields on the Fountain Inn assembly lines.

“Typically, cameras are used as a level two poka yoke to block processing of a product which is either not properly assembled or which has an incorrect component inside,” says Schaeuble. “It is a failsafe system approach to drive us to zero-defect quality.”

To learn more about the 2016 Assembly Plant of the Year, click here to watch a short video produced by ASSEMBLY Magazine.

About the Award

The Assembly Plant of the Year award was initiated in 2004 to showcase world-class production facilities in America, and the people, products and processes that make them successful. There is no entry fee. All manufacturers that assemble products in the United States are invited to nominate their plants. The winning plant receives a crystal award and a commemorative banner.The Assembly Plant of the Year award is sponsored by ASSEMBLY Magazine. The goal of the award is to identify a state-of-the-art facility that has applied world-class processes to reduce production costs, increase productivity, shorten time to market or improve product quality.

All nominees were evaluated by ASSEMBLY’s editorial staff, based on criteria such as:

•Have assembly processes been improved through the use of new technology?

•Has the plant improved its performance by making more effective use of existing technology?

•Has the plant taken steps to reduce production costs?

•Have new or improved assembly processes resulted in increased productivity?

•Has the plant used assembly improvements to reduce time to market?

•Has the plant boosted bottom-line profits and competitive advantage?

•Did operators play a role in the successful implementation of new assembly strategies?

•Has a product been effectively designed for efficient assembly?

•Has the plant attempted to protect the environment and conserve natural resources?

As winner of the 13th annual Assembly Plant of the Year competition, Bosch Rexroth’s facility in Fountain Inn, SC, received an engraved crystal award and a commemorative banner.

Previous recipients of the Assembly Plant of the Year award were Polaris Industries Inc. (Spirit Lake, IA); STIHL Inc. (Virginia Beach, VA); Northrop Grumman Corp. (Palmdale, CA); Ford Motor Co. (Wayne, MI); Philips Respironics (New Kensington, PA); Eaton Corp. (Lincoln, IL); Batesville Casket Co. (Manchester, TN); IBM Corp. (Poughkeepsie, NY); Schneider Electric/Square D (Lexington, KY); Lear Corp. (Montgomery, AL); Xerox Corp. (Webster, NY); and Kenworth Truck Co. (Renton, WA).

A nomination form for the 2017 Assembly Plant of the Year award will be available on ASSEMBLY's web site in early January.

Previous Recipients

To read about previous recipients of the Assembly Plant of the Year award, click on the links below:

- Flexibility Shines Bright at Polaris.

- STIHL Stays a Cut Above the Competition.

- Northrop Grumman Soars With Automation.

- Ford Focuses on Flexibility.

- Philips Doesn’t Rest on Lean Laurels.

- Lean Thinking Helps Eaton Stay Healthy.

- Lean Lives at Batesville Casket Co.

- Big Blue Goes Green.

- Square D Runs Circles Around the Competition.

- Lear Puts Quality in the Driver’s Seat.

- Xerox Success Is Hard to Copy.

- Technology Drives Kenworth to Excellence.