Since its introduction to automotive manufacturing in the mid-1980s, the Tox clinching process has captured hundreds of different applications. Outside of bodywork construction, clinching is being used to join sheet metal and other materials for the white goods industry, system and container construction, and climate control and ventilation technology.

The secure, button-shaped joint has a number of advantages. The simple process does not require pre- or post-machining of the materials to be joined. There is no risk of high heat input adversely affecting material structures. And, since the surfaces of the joined materials remain intact, assemblers do not have to apply additional corrosion protection. The process is cost- and energy-efficient. It can easily be automated. And, it can join a wide range of mixed materials.

Until recently, however, one question about the process has remained unanswered: Could the clinching process be used to create current-carrying joints? This question is gaining traction amid the growing electrification in automotive engineering. The number of electronic components in today’s automobiles is increasing steadily. Since these electronic components must fight for space with other assemblies, they must be light and compact. When searching for suitable joining technologies for fuse boxes, battery components or other electronic assemblies, several factors must be taken into account: What materials will be joined? How will the joining process affect component weight? Will the joint resist environmental conditions, such as vibration, heat and cold? How easy is it to integrate the joining process into an automated assembly process? How compact can a component be? And last but not least: How does the joint affect the current flow?

The Technical University of Dresden has conducted two research studies on this topic: “Electrical Property Profile of Formed Joints” (ISBN 978-3-86776-432-2) and “Optimization of Formed Joint Technologies for Contacting Electrical Conductors” (ISBN 978-3-86776-559-6). The scientists focused on clinching and joining with elements. Thermal processes, such as soldering or welding, were not considered.

The first study examines the electrical properties of aluminum materials, which were joined by clinching, rivets or other functional elements. The researchers focused particularly on the surface condition of the joined parts, as well as the geometry and the heat-treatment condition of the joint. A quality factor—a comparative value of the power dissipation in the joint in relation to the homogeneous conductor—was the criterion for assessing the long-term stability of an electrical contact. To assess the distribution of current flow within each connection point, they performed metallographic examinations of the various joint geometries and found materially bonded bridges in the neck area of clinch joints, in the foot area of semi-hollow punch-rivet joints, and in the fastened section of punch bolts. However, because semi-hollow punch rivets and punch bolts damage the coating on components, these fastening methods were rated negatively for corrosion protection.

The second study confirmed that surface coatings, like the tin coatings usual in electrical engineering, are diluted during clinching, but not damaged. In addition, the scientists investigated how or what could positively affect the electrical conductivity of a mechanically optimized joint. For clinching, the researchers showed how power transmission can be optimized via the tool geometry and the design of the clinch point. They also defined the conditions for optimal, long-term stable conductivity in the clinch point.

Electrical Conductivity of Clinched Connections

The research reports confirm what automotive suppliers have already successfully applied for attaching LEDs and power rails to a load-dispatching center: Clinching is a competitive and efficient technology for joining electrically conductive components safely and permanently. The process satisfies both mechanical and electrical requirements. Compared with thermal joining methods, there is no risk of thermally overloading surrounding materials or changing structures, and existing coatings remain intact. And, compared with mechanical fasteners, clinching produces much less electrical resistance. Electrical resistance is four times greater in a screwed connection than in a clinched connection.

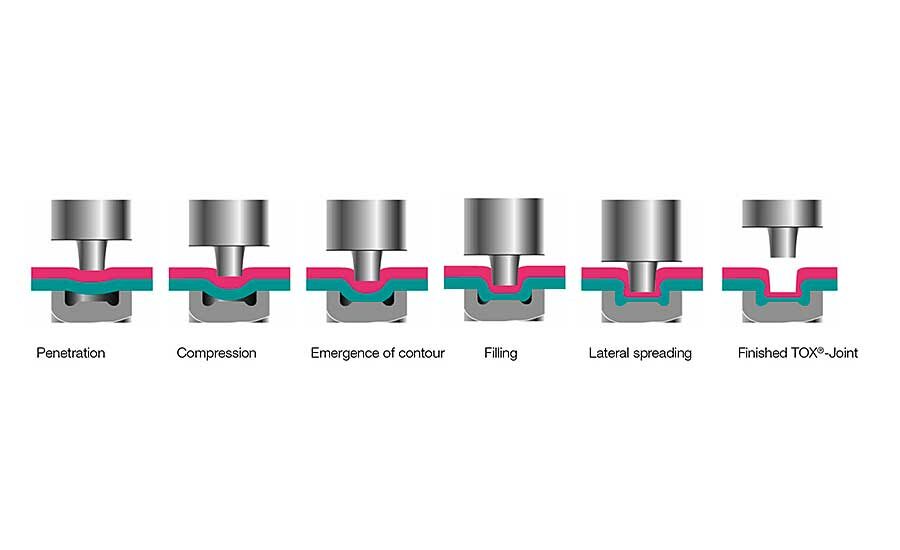

The secret of good conductivity in the clinch point is revealed when examining the joint zone at a microscopic level. The pulling-pressing process produces a positive locking and frictional connection between the two sheets. Moreover, there is a partial adhesive bond in the form of metallic micro-contacts due to the high degree of deformation as well as friction under high pressure. The joined sheets virtually flow into each other, so that the electrical resistance is reduced to a minimum. At the same time, the effective joining surface grows to almost double the size compared to screwed or welded joints. This results in an optimally conductive structure.

Risk Turns Into Security

It’s important to establish conductive connections that last in the long-term. Relaxation—a creeping dissolution under corrosion and mechanical or thermal impact—can significantly reduce conductivity. To secure the joint for the long term, important steps must be taken before, during and after the clinching process.

The risk of corrosion is eliminated from the start by the clinching process, as the surface and any coatings in the clinch point are not damaged. However, it’s important that that joint not be subjected to torque loads during use. This is best prevented during the design phase of an electronic assembly. For example, an engineer could place two clinch points close to each other, thereby preventing rotation around a single point.

Shear tension and cross tension values are not as critical to long-term conductivity, but should still be kept low. Experts recommend that the maximum force on the joint should be no more than 25 percent of the nominal maximum tensile force, if possible. To prevent relaxation in the joint under thermal influences, the maximum temperature should not exceed 90 C during operation.

The quality of the clinch point can be directly controlled by monitoring force and distance during the joining process. A maximum-strength interlock depends on maintaining sufficient strength in the neck and, most of all, ensuring proper compression of the bottom layer.

Insight Into Clinching

The basis of each clinching system is the clinching tongs, or clinching frames. The equipment includes an electromechanical servo drive or a hydropneumatic cylinder. The tools comprise punches and dies that are adapted precisely to the materials, sheet metal thicknesses and joining forces. For conductive clinch points, the best tools are the Tox round joint, the Tox Micropoint or the Tox Twinpoint. With the TWINpoint, the two clinch points are simultaneously created close to each other, securing the joint against applied torque.

The system is complemented by process monitoring sensors for automatic control of the process and sequence parameters. Accessories include a spraying system for wetting the tools and materials, and the Tox ToolCheck for continuous checking of the die.

Compared with other joining methods, such as bonding, welding, soldering and screwdriving, clinching clearly has an advantage. It does not require additional materials. It does not cut into the surface of the material, thereby safeguarding any protective coatings. It can join aluminum with copper—a material combination that is often used in battery modules—without creating an isolating intermetallic phase. The cold-forming technology is also suitable for joining sensitive battery cells without heat input.

Safeguarding the process very important. If the micro contact zones dissolve, the joint can relax, which reduces conductivity and increases the resistance in the joint. If the joint relaxes, high currents could generate intense localized heating, which can result in joint failure.

However, with the right joint design, tool design and process monitoring, clinching is a safe and efficient joining process for electronic components.