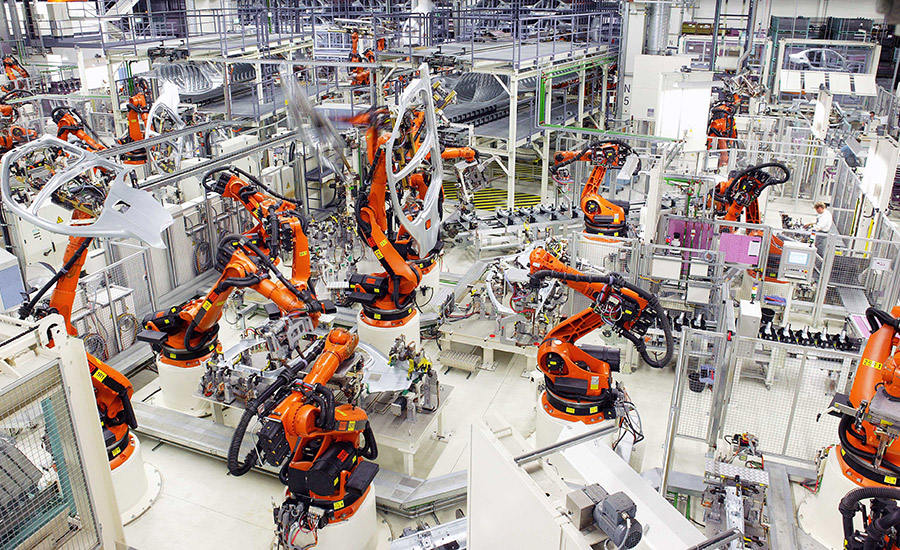

Six-axis robots are the workhorses of the automation world. Thousands of the machines are in operation inside automotive plants around the world, welding and painting car and truck bodies. Articulated robots are also used to assemble everything from chainsaws and caskets to solar panels and washing machines.

The versatile devices can approach a workpiece from any angle and can handle a wide variety of production tasks. That makes them ideal for applications that require complex motions, such as picking randomly oriented parts from a bin or conveyor.

Six-axis robots can be mounted to a floor, a table, a wall, a ceiling, a linear actuator or an automated guided vehicle (AGV). They feature a high payload capacity, in addition to wide horizontal and vertical reach.

Six-axis robot give manufacturers the ultimate flexibility, with highly articulated motion.

Unlike Cartesian robots, which have a rectilinear work envelope, or SCARAs, which have a cylindrical work envelope, six-axis robots have a spherical work envelope. An articulated robot can reach above, below, around and behind itself. Its wrist can rotate a part or turn it on an angle.

Cartesians and SCARAs are great if everything is perfectly horizontal or vertical, but six-axis robots can come at a part from an angle. The machines can reach down low, extend out or go up high.

That unique ability makes six-axis robots ideal for applications that require complex motions, such as adhesive dispensing, machine tending, packaging, painting, pick-and-place, screwdriving and welding.

Articulated robots are ideal for applications that require complex motions, such as picking randomly oriented parts from a bin. Photo courtesy Fanuc America Corp.

“Their primary advantage lies in their ability to mimic the movements of a human arm, as they possess six degrees of freedom or axes of motion,” says Ryan Guthrie, executive vice president of TM Robotics Inc., which markets Shibaura Machine’s line of products. “This flexibility allows them to perform complex and dexterous tasks with precision.

“It also means they can reach various positions and orientations in three-dimensional space,” explains Guthrie. “This versatility makes them suitable for applications that require intricate movements.”

Like SCARAs, six-axis robots have a small footprint. They can be mounted to the floor, table, wall or ceiling. An articulated robot can even be mounted to a linear actuator on the floor or ceiling to provide an extra axis of motion. Such an arrangement could enable one robot to service multiple machines. While one machine is processing a part, the robot can be loading and unloading another.

Six-axis robots are available with a horizontal reach ranging from 330 millimeters to almost 5 meters, while payload capacities vary from 0.5 kilogram to more than 2 metric tons.

Unlike other types of robots, the payload capacity of a six-axis machine can change throughout its range of motion. Cartesian and SCARA robots maintain their full payload capability over their entire range of motion.

With a six-axis robot, there may be positions where its payload capacity is less than its rated maximum, such as when the arm is at maximum extension or when the robot is lifting a part over its body.

The speed and accuracy of six-axis robots also vary with their size. For a robot with a maximum payload of 880 pounds, the joint speed might range from 95 degrees per second for the pedestal axis to 160 degrees per second for the q axis on the wrist. Repeatability is typically ±0.5 millimeter.

In contrast, for a robot with a maximum payload of 6 pounds, the joint speed might range from 210 degrees per second for the pedestal axis to 500 degrees per second for the q axis on the wrist. Repeatability is typically ±0.02 millimeter.

Despite having more axes of motion than Cartesians or SCARAs, six-axis robots are no less durable. On the other hand, six-axis robots are not as fast as Cartesian, delta or SCARA robots. They’re also more expensive. So before shopping for a six-axis robot, engineers must first decide if the application justifies the trade-offs.

“Six-axis machines offer roll and pitch capability at the end of the robot arm,” says Aaron Donlon, product manager at Epson Robots. “They’re ideal for applications that require a tool to roll in a different direction, work on a nonflat surface or follow a 3D path.

“They’re also capable of higher reaches and larger work envelopes,” explains Donlon. “Four-axis and SCARA robots tend to offer higher speeds, higher precision and lower costs, because they have fewer servomotors.”

If you just want to move parts from point A to point B, you can easily do that with a three-axis Cartesian robot. And, if you also have to rotate parts, you can simply add a two-position pneumatic rotary actuator to the Z-axis of the Cartesian, or you could use a SCARA robot.

Traditionally, six-axis robots are not as fast and precise as Cartesian or SCARA robots. That’s why they have often been relegated to dark corners of automotive plants, primarily used for welding and painting applications. In the past, the machines were large, intimidating, stayed in one place, and worked behind safety curtains or fences.

Today, however, thanks to new technology, six-axis robots are starting to appear in a wide variety of industries, such as appliance, aerospace and electronics. And, they’re being deployed for a variety of assembly tasks, such as adhesive bonding and screwdriving.

The machines are now more affordable and easier to program than ever. As a result, even small manufacturers are investing in six-axis technology.

In some factories, the machines are starting to replace conveyors and forklifts. Six-axis robots are being piggybacked onto AGVs and autonomous mobile robots (AMRs) to extend their range. The mobile platforms can easily move around a plant floor and take robots wherever they’re needed.

The demand for six-axis robots is on the rise, with a growth rate of around 30 percent annually in various industries, according to the International Federation of Robotics.

“Six-axis robots are well-suited to a wide range of applications, making them a popular choice for automation,” says Guthrie. “The development of advanced sensors, control systems and programming capabilities has made it easier to integrate and program six-axis robots into existing manufacturing environments. This has reduced the barriers to entry and made these robots more accessible to a broader range of industries.

“Another factor is cost-effectiveness," Guthrie points out. "Six-axis robots have become more affordable over time, making them a viable option for smaller manufacturers. As the prices continue to decrease, more companies can now consider implementing these robots to enhance their operations.”

Six-axis robots can approach a workpiece from any angle and can handle a wide variety of production tasks. Photo courtesy Kuka Robotics Corp.

A New Generation

Today’s six-axis robots are quite different than what was available 15 or 20 years ago. The machines are less expensive and easier to use, and there are more options available than ever. They’re also more compact.

Prices have come down dramatically in the last decade or so. Robots today are at least 25 percent less expensive than they were a decade ago. At the same time, programmability has become much easier. For instance, teach pendants are now much more intuitive.

“Traditional six-axis robots are used in a wide range of applications and industries,” says

Jessica Juhasz, manager of application engineering in the general industry segment at Fanuc America Corp. “Emerging markets and industries like food, recycling and warehousing ae growing demand for automation for the same main reason—labor shortages—but also higher demand and throughput requirements. Six-axis robots are now being put into nontraditional applications in these markets.

“[In addition, we see more] manufacturers looking for solutions that require handling significant product variability, such as mixed palletizing or depalletizing,” explains Juhasz. “Many companies have developed machine vision with AI and machine learning to solve some of these problems.”

“Robots are now quicker, more accurate, smaller and cheaper, with added reliability,” adds Nigel Smith, CEO of TM Robotics. “Compared to what used to be available in the past, the machines are now seen as more of a commodity rather than a luxury.”

Indeed, Smith says many manufacturers are no longer intimidated by six-axis robots.

“Today, they want robust, highly accurate robots that are suitable for high-speed assembly and material handling applications,” he points out. “They’re also looking to six-axis robots for increased dexterity.

“Manufacturers are trying to squeeze more and more functionality into a single cell, so the more flexible the robot is, the more likely it is able to help meet these demands,” says Smith. “Six-axis robots have more dexterity than traditional gantry-style machines.

“With more and more customers looking to install automation, the dexterity and flexibility of six-axis robots are solving a lot of issues and allowing for much higher efficiency across a wide range of industries, from automotive to medical,” explains Smith.

"A major trend is the integration of advanced vision systems that enable robots to perform tasks that require object recognition, tracking, and quality inspection," notes Guthrie. "Vision-guided robots can adapt to variable conditions and handle objects with greater precision."

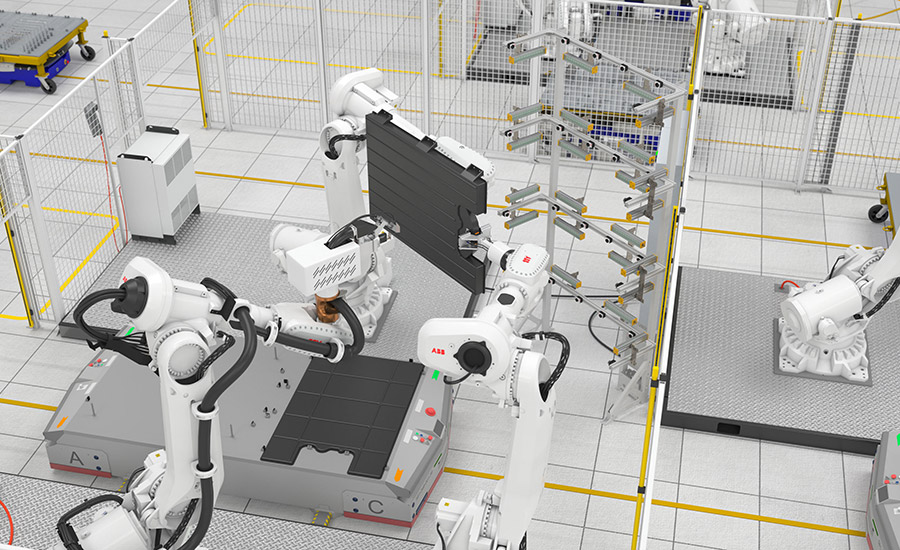

“Recent advancements in six-axis robots provide end users more model options to choose from to match their specific requirements, greater working range and enhanced accuracy,” adds John Bubnikovich, president of ABB’s U.S. robotics division. “Sustainable production is also a major priority.

“Much of the advancements of robotics for the automotive industry are targeted to OEMs and suppliers that are adapting their operations to produce electric vehicles and components, such as batteries and motors,” explains Bubnikovich.

According to Bubnikovich, automation is key to making production more resilient, efficient and faster to meet ambitious targets, which is why there’s growing demand for robots that specialize in EV power train assembly. Automakers and suppliers need robots to reduce build times, improve flexibility, simplify the production processes and drive down manufacturing costs.

“The greater range of robot options helps ensure that end users have the right variant to handle batteries of varying sizes, from individual cells and modules to complete packages,” says Bubnikovich. “They can also perform tasks such as high-precision car body assembly and spot welding, and enter restricted areas within a vehicle to install seats or dashboards.”

ABB recently expanded its large robot family with new models and 22 variants. The next-generation models include the IRB 6710, IRB 6720, IRB 6730 and IRB 6740, which are suitable for payloads ranging from 150 to 31 kilograms and reaches ranging from 2.5 to 3.2 meters.

“They offer our customers greater choice, and significant performance improvements and energy efficiency improvements of up to 20 percent,” claims Bubnikovich. “The improved energy efficiency is driven by [our] OmniCore controller and a lighter robot design.

“Featuring TrueMove and QuickMove motion control technology, the robots can achieve class-leading repeatability with a minimum of 0.03 millimeter deviation,” notes Bubnikovich. “These capabilities make the new series of robots ideal for complex tasks such as spot welding, laser welding, screwdriving and riveting, allowing automotive manufacturers to achieve high quality assembly.”

TM Robotics recently launched the latest range of six-axis robots from Shibaura Machine, known as the TVM range. They include three models, each with a longer arm length compared to previous ranges. The largest model, TVM1500, provides a maximum reach of 1,715 millimeters, providing increased flexibility in reaching workpieces.

“Despite their lightweight design, the TVM robots can handle impressive payloads,” claims Guthrie. “The TVM900 model has a payload capacity of up to 20 kilograms, while the TVM1200 and TVM1500 can manage 15 10 kilograms, respectively. The robots are fully compatible with other Shibaura Machine equipment, including the TSVision3D robot vision recognition package.”

Smaller Footprints

To meet performance and productivity objectives, more manufacturers are looking for easy-to-install robots with short cycle times that can be used in tight spaces, but are safe to operate with workers nearby. Thanks to new materials and new technology, dense robotic cells can now be designed to save on costly floor space.

Six-axis robots have evolved significantly and are now able to perform more tasks than in the past.

This has required robot suppliers to increase performance, experiment with new materials and modify the size of the machines. Today, alongside the large robots that occupy factories, it’s not uncommon to also find compact, small-sized six-axis machines built out of lightweight materials.

By using aluminum arms, for instance, robot vendors have reduced mass to improve the acceleration and speed of robots, while maintaining payload capacity. By optimizing arm design, the footprint of robots has decreased by as much as 40 percent.

“Today, six-axis robots are compact in design, faster and more precise,” says Phil Baratti, applications engineering manager at Epson Robots. “They are also using new drive technologies to manage higher payloads while maintaining rigidity.

“Features that we’ve added into all our products include a slim design and added rotational capabilities of the pitch axis,” Baratti points out. “We have cut back the material on the robots in a way that allows additional rotation range on joints two, three and five, while maintaining the integrity in the structure of the arm.

“This allows customers to take advantage of an increase in overall working space by reducing the dead space closest to the base of the robot and allowing the arm to pull in closer between joints two and three, and joint five to joint four,” explains Baratti. “Every additional degree of motion helps in tight space applications.”

The Flexion N2 features a compact arm that has the ability to fold through itself. It requires 40 percent less workspace than standard six-axis robots. Photo courtesy Epson Robots

Epson engineers took that into consideration when developing the Flexion N2 robot. Its compact arm has the unique ability to fold through itself vs. moving around itself. This reduces the number of intermediate points and shortens cycle times. As a result, the machine requires 40 percent less workspace area than standard six-axis robots. It boasts a 450-millimeter reach and 3-kilogram payload capacity.

“This patented folding arm technology has never been seen before in the automation industry,” claims Baratti. “Unlike any other six-axis robot on the market, the Flexion N2 features a unique tight space motion capability that keeps arm extremities out of the way, maximizing motion efficiency for faster cycle times.

“Applications that were previously unattainable, due to space restrictions, are now possible,” Baratti points out. “Several applications, specifically in the medical and electronics industries, require extreme precision and dexterity for handling small parts in a very tight environment.”

Epson also recently unveiled a six-axis robot designed for a variety of simple parts-transfer applications, such as machine loading and unloading, pick-and-place and adhesive bonding. The VT6L’s built-in controller saves on valuable factory space, while its slim design features a compact wrist pitch that enables access to hard-to-reach areas in confined spaces. In addition, the robot has a reach up to 900 millimeters, a payload up to 6 kilograms, and a hollow end-of-arm for simplified cabling and versatile tooling.

Besides lighter weight arms and smaller footprints, another trend in six-axis robots is mobility. Some suppliers are merging robotic technology by attaching an articulated robot to the back of an AGV or AMR, enabling the machine to become untethered and easily move around a factory.

This allows engineers to create an environment where the robot can service multiple machines, pick from multiple locations or perform multiple assembly operations at several workstations. The viable alternative to a traditional fixed robot station helps free up floor space that might normally be obstructed by conveyors.

New Applications

Collaborative robots are the hottest trend in the automation industry. Next-generation machines equipped with state-of-the-art sensor technology allow robots to operate in close proximity to humans on assembly lines.

Unlike traditional six-axis robots, collaborative machines are lightweight, flexible and can easily be moved and reprogrammed to solve new tasks. They require little or no safety barriers, which consume valuable bench and floor space, obstruct access to equipment and reduce productivity.

Cobots enable manufacturers to become much more flexible, because robots can interact closely with human assemblers. The lightweight machines are becoming more common in areas where robots traditionally worked behind safety fences.

Traditionally, six-axis robots require safety cages and other types of barriers. Photo courtesy ABB Robotics

Thanks to a broad range of possible applications, cobots open up new potential in the field of traditional automation and give engineers more leeway to implement improvements.

In the past, articulated robots were only employed in dumb, dirty and dangerous tasks, sparing humans from the drudgery of performing these types of operations. That’s why automakers have primarily used the machines for welding and painting applications. Final assembly lines were considered too complex and too unsafe for automation. However, that scenario is starting to change.

Automotive engineers are now adopting the technology in nontraditional production processes, such as trim lines. In addition, the COVID-19 pandemic, ergonomic issues and electrification efforts are spurring new robotic applications for adhesive and sealant dispensing, bin picking, nut running, part insertion, screwdriving, and test and inspection.

“The traditional approach to automation has been all or nothing, with big robots and big safety guarding,” says Joe Campbell, a robotics industry veteran who recently retired as senior manager of strategic marketing and applications development at Universal Robots USA Inc. “That has been a constant struggle for decades. Engineers could use automation for most of their assembly tasks, except for the last 10 percent.

“We’re starting to see six-axis cobots deployed to address ergonomic issues in final assembly applications,” explains Campbell. “Because cobots can work in close proximity to humans, workstations don’t have to be fenced off and totally guarded like in the past. Operators can work side by side with cobots. Humans can focus on tasks that are easily accessible, while the machines work on things that are more difficult to reach.”

Final assembly has some of the most demanding processes and the most operator engagement in the auto industry. It involves complex trim lines where operators manually install a wide array of components such as carpeting, doors, instrument panels, interior lighting and infotainment systems, seats and other subassemblies.

In addition, final assembly involves a variety of just-in-time and just-in-sequence processes that must be precisely choreographed. Since most vehicles have four or five trim levels, accuracy, error proofing and process control are essential.

The “killer app” for robotics in the auto industry has always been welding. The return on investment for that application revolves around ergonomics and safety, labor cost savings, increased throughput and improved quality.

Traditionally, final assembly has been difficult to automate because of flexibility issues and challenges. That’s why final assembly, which is currently less than 5 percent automated, is considered to be the “final frontier” of automation in the automotive industry. Engineers hope to eventually apply artificial intelligence to robotics to tackle variation and model mix.

One reason why final assembly lines are only 5 percent automated is that it’s a harder problem area to solve than painting or welding applications. For instance, there’s a lot more variation. Design changes show up in places in final assembly that don’t show up in the body shop.

There are also tolerance stackups in final assembly as more components are installed in a vehicle. In addition, many of the assembly tasks require a large degree of dexterity.

While there are some robots in use on final assembly lines, the main thing that has held back automation is that many systems integrators view it as too risky and a hard problem to tackle. To address that issue, some entrepreneurs are developing software programs that address the challenges.

Large and Small Extremes

Six-axis robots are also growing larger and smaller. At one extreme, there are massive machines that can lift extra heavy payloads. On the other end of the spectrum, tiny tabletop units can carry out many of the same functions as their big siblings.

Mega material handling robots are ideal for moving automobile, tractor and truck frames, engine blocks, boat hulls and heavy aerospace structures. They eliminate the need for overhead gantry cranes and hoists.

Large six-axis robots eliminate the need for overhead gantry cranes and hoists. Photo courtesy General Motors

A heavyweight battle for the title of world’s largest and strongest robot is being waged by ABB, Fanuc, Kawasaki and Kuka.

ABB’s IRB 8700 has a reach of 3.5 meters and can handle payloads of up to 800 kilograms. Fanuc’s M-2000iA/1700L can lift objects that weigh up to 2,300 kilograms, with a reach of 4.6 meters. Meanwhile, Kawasaki’s MG15HL can accommodate payloads up to 1,500 kilograms. It boasts a 4-meter horizontal and vertical reach. Kuka’s KR 1000 titan robot is no slouch either. It can lift up to 1,300 kilograms with a reach of more than 2 meters.

The massive machines have wowed attendees at recent trade shows. But, some manufacturers are investing in giant six-axis robots to take on tasks that were previously performed by forklifts, hoists, lift-assist devices, overhead cranes and other types of material handling equipment.

The super heavy payload machines are especially popular with manufacturers of cast and forged metal parts. They’re also attractive to companies that need to move automotive floor pans, car bodies, rear-axle assemblies, large household appliances, tractors or other bulky objects, such as sections of airplanes, railcars and ships. In addition, large six-axis robots appeal to manufacturers of batteries and electric vehicles.

More than a decade ago, Ford Motor Co.’s Michigan Assembly Plant deployed a heavy-duty six-axis machine from Fanuc that employees affectionately dubbed “Godzilla.” The big robot serves as a vehicle transfer system in the body shop. It precisely picks up bodies off pallets and places them on skids that carry them through the paint shop.

The robot replaced the need for traditional lift and transfer systems that use mechanical tooling. That reduced floor space in the 2012 Assembly Plant of the Year by more than 40 percent. It also decreased system complexity by removing extensive hard tooling. In the past, the transfer process required the use of forklifts and other nonflexible material handling devices.

According to ABB’s Bubnikovich, large six-axis machines such as the IRB 8700 are intended for palletizing applications and for moving car bodies around auto plants. The robot automatically adapts and adjusts its speed to accommodate heavy and wide parts.

It only has one motor and one gear per axis, while most other robots in this size class use dual motors and gears. Fewer components and shorter cycle times make the machine 25 percent faster than comparable robots in its payload range.

This six-axis robot weighs less than 5 kilograms and has a payload capacity of 0.5 kilogram. Photo courtesy Mecademic Inc.

At the other extreme is the Meca 500 from Mecademic Inc., which the Canadian firm claims is the world’s smallest six-axis robot. It weighs less than 5 kilograms, has a payload capacity of 0.5 kilogram, a repeatability of 0.005 millimeter and a maximum reach of 330 millimeters.

The benchtop unit is 12 inches tall, with a base the size of the palm of a hand. A compact controller is embedded in the base of the machine. Potential assembly applications include electronics, medical devices and watchmaking.

“It is not only twice as small as any other small industrial robot arm, but has no bulky controller cabinet and no thick tangling cables,” says Ilian Bonev, Ph.D., director of the Control and Robotics Laboratory at l’Ecole de Technologie Superieure (ETS) in Montreal and co-founder of Mecademic. “Its controller is fully embedded in its palm-sized base.

“Unlike virtually all other industrial robots, we’ve designed our [machine] as a component, rather than as a complex standalone system,” notes Bonev. “We’ve also designed a very simple communication protocol with less than 50 proprietary commands.

“We’re addressing a growing demand for precise, delicate manipulation of small parts in confined spaces,” claims Bonev. “Products are getting smaller and need to respect close tolerances. Factories lack space and need to be more energy efficient.

“We thus enable a whole new range of applications, products and discoveries that were nearly impossible before,” says Bonev. “Most of our customers simply couldn’t perform their task before because of lack of space.”