Wind power has grown significantly in the past 30 years. Advances in wind energy technology have decreased the cost of wind electricity generation. Government requirements and financial incentives for renewable energy in the United States and in other countries have also contributed to growth in wind power.

In fact, total annual U.S. electricity generation from wind energy increased from about 6 billion kilowatt-hours (kWh) in 2000 to about 380 billion kWh in 2021. In 2022, wind turbines were the source of more than 10 percent of total U.S. utility-scale electricity generation.

For optimal energy generation, turbines must be located in areas that are windy, such as plains, ridge lines and offshore areas. In the latter case, turbines must be designed to withstand extreme forces from waves, currents and weather. They must also resist damage from mussels, algae and other sea life. The concern is that, over time, the added weight of thousands of marine organisms could adversely affect the load-bearing capacity of support structures. They could also impede the flow of water around the structures, leading to greater drag.

In 2022, wind turbines were the source of more than 10 percent of total U.S. utility-scale electricity generation. Photo courtesy U.S. Department of Energy

The EnviSim4Mare research project was launched two years ago to investigate what types of sea life grow on marine structures and how those organisms could affect the load-bearing capacity of offshore wind turbines and other structures. For this purpose, a new large-scale saltwater research facility was built at the Leichtweiss Institute for Hydraulic Engineering and Water Resources in Braunschweig, Germany.

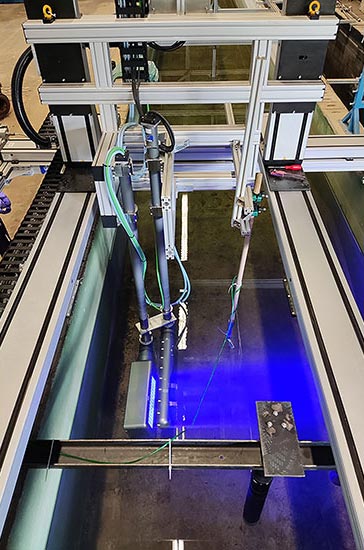

The centerpiece of the new facility is a large, saltwater wave pool that enables researchers to study how water flows around underwater structures. The pool was designed by researchers Mario Welzel and Clemens Krautwald.

Thousands of tiny plastic beads distributed evenly in the water enable the researchers to easily visualize the velocity fields of waves and currents as they flow around structures. Photo courtesy Max Fuhrmann and TU Braunschweig

In the initial phase of the project, the researchers placed a variety of vertical posts in the pool. Some posts had smooth surfaces. Others were covered with carpeting or sandpapers of different grits. The piles of the carpeting varied between smooth to fluffy to simulate the foundational structures of offshore wind turbines and various types of vegetation.

The water in the wave channel flows around the posts. Thousands of tiny plastic beads distributed evenly in the water enable the researchers to easily visualize the velocity fields of the waves and currents as they flow around the structures. Vision systems and LED lighting make it possible to study and record the flow patterns.

As a wave rolls towards a post, a wide stripe of purple light from an LED illuminates the channel. As the water flows around the post, the beads are visible in the light, enabling the researchers to measure speed, force, turbulence and flow patterns. Welzel and Krautwald vary the waves in the pool and the surface friction of the posts to change the water flow patterns.

“With our 4D flow field measurement, we can measure the flow without influencing it as with other methods,” says Welzel.

Cartesian Robot Positions Cameras

For the wave pool setup to work, the researchers needed a way to accurately and reliably position four cameras and multiple LED lights above the water. The positioning system would have to span wide distances, support a load of 800 kilograms, and resist a saltwater environment.

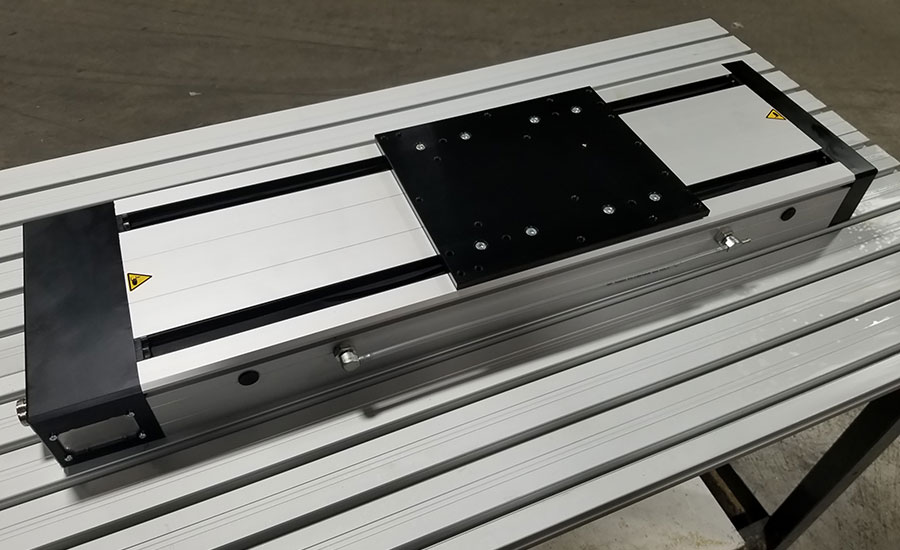

A large Cartesian robot developed by Isel Automation solved the problem. Isel engineers constructed the robot from LES 5 precision rodless linear ballscrew actuators. The actuators have two guide rails, making them capable of handling lateral forces and meeting the straightness requirements of the project. Available with travel lengths of 5 to 107.2 inches, the actuators have a wide, 8.8-inch base that can support cantilevered loads.

Four cameras and LEDs are attached to the actuators, which support a load of 800 kilograms. Photo courtesy Max Fuhrmann and TU Braunschweig

The actuators can be used for one-, two- or three-axis motion systems. There are built-in limit switches at both ends of travel, and optional external mounted adjustable limit switches are available. They can be equipped with internal or external motor mounts. Motor options include stepper motors or brushless servomotors with or without failsafe brakes. Optional positive air pressure fittings keep dust and dirt out. Ballscrew pitches of 2.5, 5, 10 or 20 millimeters are available for fine resolution or high speed.

Available with travel lengths of 5 to 107.2 inches, LES 5 linear actuators have a wide, 8.8-inch base that can support cantilevered loads. Photo courtesy Isel Automation

So far, the system has been a success, enabling researchers to study the effects of force, shedding vortices and flow patterns. More than 400 experiments, with different camera settings, have been run. The researchers initial data indicate that the growth of mussels and algae must be taken into account during the planning and construction of wind turbines.

“We need a better understanding of the system here. Because the less we know about the processes and influences, the more safety factors have to be built in,” explains Welzel.

“In addition to the piles of the huge, firmly anchored wind turbines, cables and pipelines are also affected by mussel growth,” adds Krautwald. “These basic tests of different piles are intended to improve our understanding of the process.”

The next step in the project is determine how much sea life grows on underwater structures and how quickly it accumulates. The researchers have deployed test structures at various offshore locations in the North Sea around Heligoland Bight and the Nordergründe Offshore Wind Farm. The researchers will measure the structures over time to learn how algae, barnacles and mussels grow on them.

ASSEMBLY ONLINE

For more information on motion control technology, read these articles:

Linear Actuator Improves Ergonomics at Printer Manufacturer

Actuators Help Sigma Integrale Simulate Drag Racing

Clean Assembly Lines Require Clean Actuators