Traditionally, soldering is done by hand. That’s fine for some high-mix, low-volume assembly applications. It’s also great for rework and repair tasks.

However, for low-mix, high-volume applications, manual soldering is not ideal. In addition to ergonomic issues due to repetitive motions, long-term exposure to soldering fumes poses health risks to assemblers. Automation is a much better alternative.

In an era where precision and efficiency are paramount, soldering robots have become essential for electronics assembly applications. A variety of machines can be used, including collaborative, SCARA and six-axis robots.

“Inevitably, there will be some electronic components that you can’t send through reflow ovens or wave machines that are used for bulk soldering applications,” says Will Hunter, CEO of MTA Automation Inc. “Those joints have to be hand-soldered, which is tedious and unreliable.

“The biggest benefit of using robots has always been consistent quality and increased throughput,” explains Hunter. “Today, more engineers are also looking at robots because of severe labor shortages. Manufacturers just can’t find people willing to do soldering by hand.”

“The foremost advantage of employing soldering robots lies in their unwavering precision,” adds Nigel Smith, CEO of TM Robotics, the distributor of Shibaura Machine (formerly Toshiba Machine) industrial robots. “In manual soldering, human error is an ever-present risk, and as electronic components continue to shrink in size, the potential for inaccuracies grows exponentially.

“Instead, robots offer improved accuracy, repeatability and throughput throughout the soldering process,” notes Smith. “This eliminates the unpredictability associated with manual labor. By removing human error from the equation, we maintain absolute positional accuracy, which is a crucial factor in today’s intricate electronics landscape.

“When soldering manually, errors are not only common, but also inconsistent and challenging to detect,” warns Smith. “Soldering robots can help reduce errors by allowing for quick reprogramming, which prevents recurring mistakes.

“Moreover, as electronic components continue to shrink, the disparity between manual and robotic soldering capabilities becomes more pronounced, highlighting the pivotal role of robot technology in improving throughput of electronic components,” says Smith.

Soldering stands out in the realm of robotic assembly processes due to its precision requirements and the nature of the material involved. Unlike adhesive dispensing or welding, where a robot may need to accurately follow a path or dispense at specific spots, soldering demands a meticulous approach to join components effectively.

“Speed control is often crucial in soldering to ensure that material is dispensed smoothly,” says Smith. “Over the past 10 to 15 years, robotic soldering has undergone significant advancements.

“Robots used for soldering today boast superior control, speed and accuracy,” claims Smith. “Manufacturers are seeking features that allow for even finer control over the soldering process, as well as integration with advanced technologies for improved monitoring and quality assurance.”

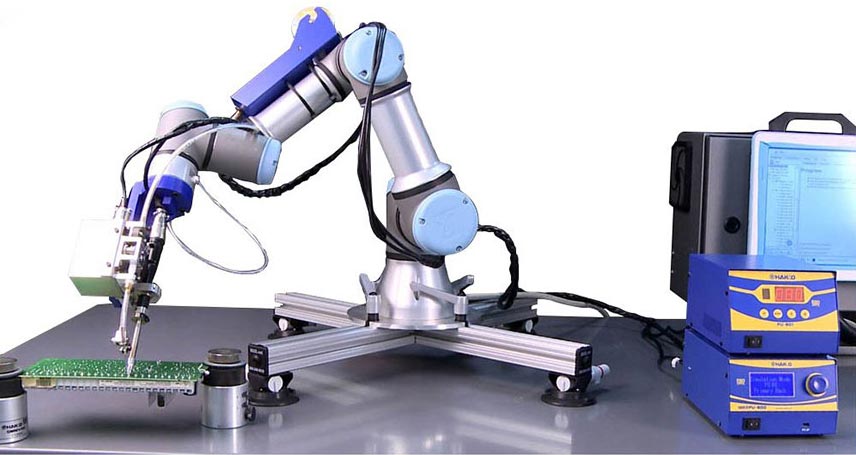

Tabletop robots offer a good way for manufacturers to transition from manual soldering to robotic soldering operations. Photo courtesy MTA Automation Inc.

Soldering robots are primarily used to assemble electronic components. Other applications include EV battery modules, battery packs and solar panels.

“We don’t see much demand for consumer electronics anymore,” says Hunter. “Most interest now comes from contract manufacturers and Tier 2 or Tier 3 automotive suppliers.

“We see fewer soldering applications at the printed circuit board (PCB) level and more related to attaching those boards to other things,” explains Hunter. “Many applications relate to automotive components. For instance, companies want to solder components used in small, compact electric motors that are used in power seats, windows and other devices.

“Manufacturers also want to produce high-mass solder joints that can accommodate today’s higher amperages,” Hunter points out. “So, we’re coming up with systems that allow us to put more heat in the joint faster.”

“There’s surprisingly more electronics assembly done in the United States than most people realize,” says Will Healy, global segment manager for welding at Universal Robots (UR). “There are a lot of customized applications where companies are producing just a few hundred items at a time for use in things such as construction equipment or lighting products.

“They’re not necessarily making boards from scratch,” notes Healy. “Instead, they’re adding on to or modifying a board for use in a specific type of product.”

“We have seen a remarkable uptick in inquiries regarding soldering robots in recent years,” adds Smith. “This surge can be attributed to several factors, including the escalating cost of labor in the United States.

“As the cost of labor rises, the allure of automated soldering becomes more appealing,” notes Smith. “Additionally, reshoring efforts, with companies bringing their manufacturing back to the United States, have driven the demand for automated soldering and robotics.”

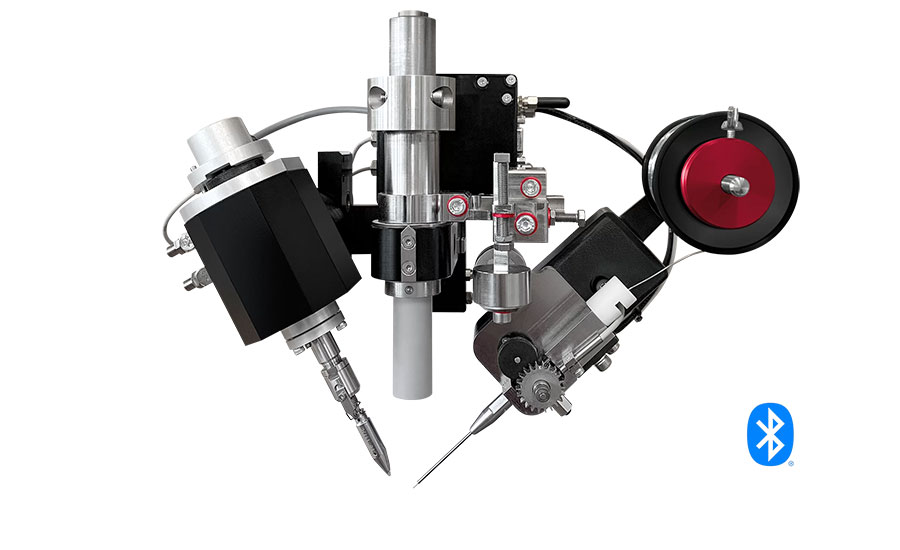

This kit includes an iron and a wire feeder that enables collaborative robots to perform soldering tasks. Photo courtesy Universal Robots

Tools of the Trade

Several different types of robots can be used for soldering applications, including cobots, SCARAs and six-axis machines. Each has pros and cons that engineers must carefully consider.

“Unlike traditional types of robots, cobots enable workers to still be in the work space,” says UR’s Healy. “It’s a good way to maximize the space that manufacturers already have on their plant floor. After conducting a safety assessment, you can take an existing workstation that you can’t staff because of labor shortages and make it productive again.”

“Cobots enable one person with a skill to operate two or three workstations,” Healy points out. “They apply their knowledge while doubling or tripling their productivity. Cobots also make it easier to change over production vs. traditional types of robots, because there’s much less programming required.

“Our smaller payload machines, such as the UR3 and UR5, are popular for soldering applications,” explains Healy. “We also partner with a network of partners that pair their existing technology with our robots. That makes it easy for engineers to get a machine up and running quickly.”

A good example is American Hakko Products Inc. The Hakko Soldering Kit consists of an iron and wire feeder that enable UR cobots to perform a variety of soldering tasks.

“This product is ideal for automating virtually any hand soldering process by increasing overall throughput and consistency of the solder joints,” says Healy. “The FU-500 intelligent solder feeder lends a helping hand to automatically feed the solder wire to a specific position and allows for easy adjustment of the solder feed position, which is critical for automated systems.”

The device also features a compact driver unit that allows the feed to be brought closer to the iron, increasing the accuracy of the amount of solder fed. With an optical sensor, the FU-500 can detect solder clogging, slipping and the end of the solder roll.

The solder feeder is equipped with a mechanism that perforates into the solder wire as a countermeasure against flux and solder splash. The FU-601 robotic integration soldering module features Hakko’s high-performance composite tips with accurate temperature for consistent solder joints. The tips can be easily and quickly replaced, then realigned using a tip alignment tool.

Many manufacturers are investing in soldering robots because of labor shortages. Photo courtesy TM Robotics.

Traditionally, SCARAs are the preferred choice for robotic soldering applications, because of their high speed, high precision and small footprint. “SCARA robots are particularly well-suited for soldering applications for several reasons,” notes Smith. “First, they excel in simple programming, making it easier to set up and adapt soldering tasks. Second, SCARAs offer highly accurate point-to-point positioning, ensuring precise solder joints. They also provide swift movements between points.”

“SCARA robots are commonly used for robotic soldering applications in the electronics industry, especially if it’s a component with a flat profile, like a PCB,” says Carlos O’Farrill, senior business development manager at Kuka Robotics Corp. “Six-axis robots typically make better sense for assembling things that are three-dimensional, such as battery modules or packs. They provide the ability to reach large parts, such as solar panels, and can reach parts from different angles or sides.”

Several years ago, Kuka partnered with Alnea to produce a compact soldering cell that features a KR 6 R900 robot and a Zeus controller. According to O’Farrill, the system can reduce production time by up to 50 percent. The SCARA robot controls the motions of the soldering iron while holding PCBs in a fixed position.

Tabletop robots offer a good way for manufacturers to transition from manual soldering to robotic soldering operations. That’s why MTA Automation developed the TR300 platform. It provides a cost-effective way to automate existing hand soldering processes without the cost of a fully automated systems. The four-axis robot features 0.02-millimeter repeatability and a 300-by-300-millimeter work envelope.

“The TR300 nicely fills the gap between highly skilled labor and expensive fully automated machines,” claims Hunter. “The purpose-built robot performs the solder process, so the operator does not need special training and certification.

“Because operators load and unload parts, the robot does not need nimble motion control or complex vision systems for part handling,” explains Hunter. “The machine and operator complement each other in a cost-effective symbiosis, so manufacturers can fill their labor gap with relative ease.

“This tabletop platform is ideal for applications where human dexterity is required to position parts,” Hunter points out. “Operators can load and unload parts in offline fixtures to minimize machine downtime.

“The ballscrew axis and motors provide fast, repeatable motion,” says Hunter. “They are strong enough to support our heads, which include an anti-jam wire feeder system and solder wire spool. There is no need to push solder wire through lengthy and problematic feed tubes.

“Therefore, the soldering process is more accurate and reliable than feeding the wire long distances,” claims Hunter. “Similarly, we preplumbed a large fume extraction hose with the nozzle located directly above the solder joint. Light curtains and safety guarding are also standard features.”

MTA Automation’s newest product is the MSH150 solder head, which was released about a year ago. The standalone unit is a compact, all-in-one package.

This solder head can be used with a variety of collaborative, SCARA and six-axis robots. Photo courtesy MTA Automation Inc.

Everything is contained in one unit inside the head, including the soldering iron, wire feeder and controller. The plug-and-play device can be used with collaborative, SCARA and six-axis robots. It can also be installed on any standard robot, including machines from ABB, Epson, Fanuc, Kuka and UR.

Shibaura Machine’s latest product offering in the realm of robotic soldering is the new THE SCARA Series, which includes high-load performance robots designed for synchronized control and tracking precision. The machines are designed for assembly and inspection applications in the electronics equipment and automotive component industries.

“The THE800 and THE1000 are cost-effective options that cater to both users and system integrators,” says Smith. “These robots deliver unparalleled precision, quality and performance, redefining the boundaries of what is possible in automated soldering. They are complemented by the TS5000 controller, which boasts position control for pinpoint accuracy and shorter cycle times.”