Weiss has optimized its HP 70 pick-and-place module for long strokes with short cycle times. A flat ribbon cable now protects the pneumatic and signal lines instead of a spiral hose. This allows the unit’s speed and reach capabilities to be fully utilized.

The machine has a maximum speed of 4 meters per second, a maximum acceleration of 40 meters per second squared, and a maximum horizontal stroke of 325 millimeters. In short cycle time applications, high-speed motions exert high loads on the cable connections and cable conduit. A flat ribbon cable is more durable. It combines four pneumatic lines and four signal lines. It is quieter, more stable, and less susceptible to wear. The ribbon cable is available as an option or spare part. Any HP units already in use can be retrofitted with the new cable.

The new HP 70 variant is designed for clean room applications. It’s also equipped for safety-related applications. The encoder attachment ensures functional safety, and each motor is equipped with over-temperature protection.

The compact module is 60 millimeters wide and weighs only 9 kilograms. The 70-millimeter vertical stroke never extends beyond the body of the module.

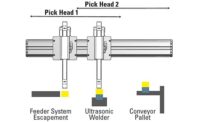

The freely programmable unit works seamless with the company’s rotary indexing tables and linear transfer systems. Weiss application software simplifies programming and operation. Users do not require in-depth control knowledge. Up to 32 axes can be controlled with the software.

See this product at The ASSEMBLY Show South, April 30-May 2.

Weiss North America Inc.

www.weiss-world.com