Programmable Rotary Tables have a multitude of applications in a wide variety of industries. They are used to position components that need to be rotated in specific, very accurate degrees of rotation so that manufacturing operations can be performed. Programmable rotary tables can be used to position parts for welding, machining, assembly, inspection or any number of operations requiring components to be presented at precise angles.

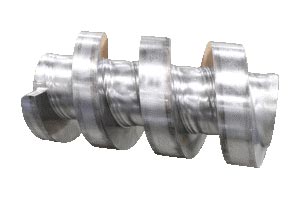

Traditional rotary index tables are positioned using mechanical components called ‘cams indexers’ in order to repeatedly rotate the table into a precise position. The cam indexers provide precise positioning to position a load using a mathematical motion curve that is machined into the cam. The mechanics provide a smooth and highly repeatable motion.

Traditional rotary index tables are positioned using mechanical components called ‘cams indexers’ in order to repeatedly rotate the table into a precise position. The cam indexers provide precise positioning to position a load using a mathematical motion curve that is machined into the cam. The mechanics provide a smooth and highly repeatable motion.

Image courtesy of Motion Index Drives

Image courtesy of Motion Index DrivesThese tables are ideal for consistently delivering components to a fixed and repeatable angular position. They work well for applications that require high precision positioning at a lower cost. A traditional rotary index table may have very limited control functionality, perhaps using a sensor to determine where the indexer is along its rotational cycle. The sensor might be used to stop and start the cam motion in order to increase or decrease the ‘dwell’ period that occurs between rotary motions. This is a relatively inexpensive form of ‘programming’ a rotary index table.

An alternative to the traditional rotary index table is a programmable rotary table. A fully programmable rotary table uses a servo motor as the drive motor. A servo drive motor and programmable control system offer up nearly infinite indexing possibilities.

A simple application for a programmable rotary table is when an operation may require different or extended dwell times. A programmable rotary table enables a feedback system that allows the table to progress when an operation is satisfactorily completed.

A more advanced application for programmable rotary tables is when multiple products are run across the same production line. Having the ability to program the rotary motion of the table enables any number of product profiles to be run on the same machine, saving significant capital costs vs having to purchase multiple rotary index tables.

It’s important when selecting a rotary table to work with a company that has extensive applications engineering expertise. Matching the cam type, the drive and control system and the mechanics of the table to ensure that the system will perform with the moment of inertia of the component being handled, the cycle times and long-term durability of the table is vital.