ROME—Automation firm Comau and aerospace supplier Leonardo S.p.A. are working together to develop self-adaptive robotic technology that can autonomously inspect helicopter blades up to 7 meters long.

The companies have been testing the smart inspection system in Anagni, Italy, over the past year. The system may now move to another site to deliver enhanced capabilities for maintenance, repair and overhaul services.

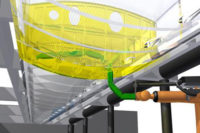

Leveraging cognitive robotics, advanced vision systems and artificial intelligence, the system autonomously performs tapping tests and multispectral surface inspection along the nonlinear blade to measure and verify the structural integrity with a granularity exceeding thousands of points. Robotized inspection ensures 100 percent accuracy within the self-adaptive process. In contrast, the manual inspection process is labor-intensive, physically demanding and dependent on the experience of the worker.

Each company shared specific competencies to optimize the end-to-end inspection process. These include intelligent algorithms and advanced path planning that allow the robot to see and respond to its surroundings, as well as a comprehensive data acquisition and processing infrastructure that facilitates optimized sound and image recognition. As the blades are mechanically stimulated by the smart robot, the sound response is both recorded and photographed using a multi spectral camera to detect hidden and superficial defects.

Another powerful feature of the system is that it automatically senses the environment. It first localizes the blade, which has been placed on its supports by the operator, detects any obstacles and then calculates both cycle time optimization and collision-free path planning.

All this technical complexity is hidden behind a simple and effective user interface based on low-code programming. This allows the operator to program the robot using simple, human commands: look for the blade, find the position and execute the action required.

Such intelligent automation helps reduce process complexity and optimize outcomes by enabling the robot to perceive and see its surroundings, automate its decision-making and intuitively optimize the inspection processes. This grants greater flexibility without sacrificing precision or repeatability.