BRISTOL, England—Q5D Technology Ltd. has received a $3 million investment led by Lockheed Martin Ventures, the investment arm of Lockheed Martin Corp. The funds will be used to further develop hardware and software tools for automating the wiring harness assembly process.

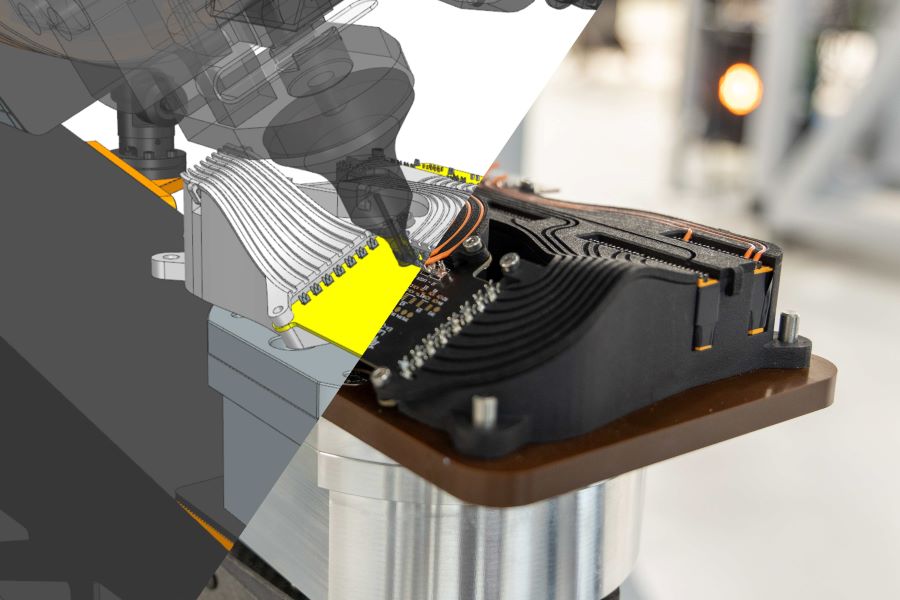

Q5D has developed a robotic system that can attach wiring and printed electronics directly onto product surfaces. “This automation offers not only improved quality and reliability, but also significant reductions in manufacturing costs compared to traditional manual processes,” claims Stephen Bennington, CEO of Q5D.

“The CY1000 5-axis CNC robotic handling cell automates the addition of electrical wiring and terminations in products, delivering 5 to 10 times productivity improvements,” explains Bennington. “Its unique ‘Electrical Function Integration’ technology mitigates the need for expensive, heavy and potentially unreliable wiring harnesses; offers greater flexibility to product designers; and reduces both manufacturing and supply chain costs and risks.

“The machine also offers precision polymer deposition and deposition of conductive inks,” Bennington points out. “All of this can be done on complex-shaped surfaces.

"We are thrilled to have Lockheed Martin as a strategic investor," says Bennington. "The potential market for our technology within the defense sector, for both printed electronics and wiring products, is vast. Lockheed Martin's guidance and support will spearhead our entry into this market in the U.S. and beyond."

"We see the opportunity for increased versatility and agility in Q5D's technology," adds Chris Moran, vice president and general manager of Lockheed Martin Ventures. "Wiring is a complex and expensive aspect of the manufacturing process. Q5D's technology can offer flexibility with the potential for hardware to efficiently switch between manufacturing different parts without compromising quality.”